This article is part of an editorial collaboration with BCorporation. The BCorp Series can be found here. The original publication can be found here.

Through Recycling Programs and Consumer Education Opportunities, B Corps Broaden the Circular Economy and the Circle of Earth-Friendly Practices

Employees at Tom’s of Maine are encouraged to use 5%—or 12 days a year—of their paid time volunteering for causes they’re passionate about. They contribute hundreds of hours each year to community causes. (Photo courtesy Tom’s of Maine)

With a recent Gallup poll showing that two-thirds of Americans believe global warming is caused by human activities and more than half responding that they are “concerned believers” who think it will pose a serious threat during their lives, the opportunity is high to help people take action to mitigate the effects of climate change.

Certified B Corporations consider the environment as one of many stakeholders in their business operations, and many B Corps provide products and services that help people reduce their impact on our planet.

Newly certified B Corp Tom’s of Maine has for nearly 50 years provided personal care products made from natural ingredients and encouraged customers to return the packaging for recycling if they’re unable to do so locally. In recent years Tom’s of Maine has donated to nonprofits that promote water conservation through education and other programs.

Eliminating waste is the mission at Rubicon Global, which helps its clients reduce waste and maximize recycling efforts. Through its global operations, Rubicon helps people reduce their impact on the Earth and builds more sustainable communities.

These two B Corps share more about their Earth-friendly products and policies and provide inspiration for other companies looking to do the same.

Tom’s of Maine and Rubicon Global are part of the community of businesses that have used a third-party verification of their impact. Use the free B Impact Assessment to evaluate your company’s impact on all stakeholders, including the environment, your workers, your community and your customers.

Sustainable From the Start

While Tom’s of Maine is a newly certified B Corp, its mission always has included the environment as a stakeholder. Tom’s was founded in 1970 by Tom and Kate Chappell, who wanted to create natural personal care products — free of artificial colors, flavors, fragrances, preservatives, and sweeteners — while contributing to their Kennebunk, Maine, community.

Nancy Pak, general manager and vice president at Tom’s of Maine, says the company’s initial product — Clear Lake laundry detergent — made some retail breakthroughs because of its natural ingredients and because the Chappells encouraged customers to return empty packaging to Tom’s of Maine by mail so the containers wouldn’t end up in the landfill.

“They believed you could produce great natural products, and also be profitable and protect the planet,” she says. “Their vision to protect the planet is held by all employees, from when the company started to present day. We’re always looking for ways to improve.”

Through the years, Tom’s of Maine has expanded its product line to include toothpaste, mouthwash and other oral care products; deodorant and antiperspirant; and soap and body wash that meet its natural, sustainable and responsible stewardship standards.

“Over the decades we’ve learned there are some ingredients we will not put in products. We absolutely have to source ingredients from a sustainable source. They can’t be overly processed,” Pak says. “It’s an ongoing journey. It’s the way that we do business and the way that we run the company and treat all of our team members.”

Tom’s of Maine also has focused on making its product packaging more sustainable and responsible to reduce trash that heads to landfills. Pak points to its soap packaging as one recent example that other companies could employ.

“We took our bar soaps out of boxes and into recycled paper wrap. You can smell the natural fragrance through the paper,” she says. “Our deodorant barrels are made with 41% recycled content, and our toothpaste cartons are made with soy-based inks and certified 100% recycled paperboard.”

While the personal care industry as a whole continues to make strides toward Earth-friendly packaging, Pak says, Tom’s of Maine has goals to use more post-consumer recycled content and explore packaging that can easily be recycled at home.

Tom’s of Maine strives for more sustainable product packaging options, including toothpaste cartons made with soy-based inks and recycled paperboard. (Photo courtesy Tom’s of Maine)

A Strong Natural Care Brigade

Tom’s of Maine sets company goals in several areas, including waste, energy use, packaging and community involvement, and publishes its progress in its annual Goodness Report. In measuring its environmental footprint, the company recently expanded its data to include its supply chain and consumers. That revealed that 98% of its water consumption came through consumer use — and led to a new focus on consumer education.

Rob Robinson, brand and goodness leader at Tom’s of Maine, says the B Corp is partnering with The Nature Conservancy to help inform consumers. As part of its commitment to donate 10% of profits to nonprofits, Tom’s of Maine has given more than $2 million to The Nature Conservancy for water conservation and restoration efforts, with a portion of that devoted to educating consumers about water sources and use.

The Natural Care Brigade, created seven years ago in a partnership with TerraCycle, is another consumer-oriented program designed to reduce waste sent to landfills and serve as a fundraising opportunity for community organizations.

“Consumers can collect and send in their personal care waste, which is recycled into durable goods like picnic tables and park benches. It’s actually being made into something that’s going to have a longer life,” Robinson says.

To expand the impact of the Natural Care Brigade, Tom’s of Maine decided to accept waste from any brand of toothpaste or other personal care products. Once consumers sign up for the program — which is offered nationwide in the United States — they receive labels to ship their waste for free to recycling points. For every piece they send in, they can earn funding for a designated nonprofit organization or school.

With more than 15,000 Natural Care Brigades that have recycled more than 1 million units of packaging waste, the company sees the program as a success to build upon.

“Part is just educating consumers so they start to think more about what happens when they toss toothpaste into a trashcan,” Robinson says.

More Than Product and Profits

The new B Corp certification is an external sign of validation for Tom’s of Maine everyday business practices, Pak says, and has boosted employee engagement and pride.

“It’s just reinforcing the good that we do for the planet, community and consumers,” she says. “It reminds them that their work is meaningful and makes a difference. They’re contributing to more than just product and profits.”

As part of working toward its goal of zero waste by 2020, Tom’s of Maine sought ways to handle excess toothpaste from its production process at its Sanford plant. The B Corp discovered that the natural toothpaste could be composted in Maine, and last year, the company composted more than 17,000 pounds of toothpaste. (Photo courtesy Tom’s of Maine)

With lofty internal goals — including zero waste at its Sanford, Maine, production facility by 2020 — Tom’s of Maine continues to strive for improvement in its operations, Pak says.

“The other piece is that having the certification is not an end game, not the final step,” she says. “It’s a starting point as a B Corp: What are we doing well and where can we get better? When you look at the dimensions of all the things that are important — and start continuously looking for ways to add value and improve — that’s an amazing motivator. We’re living the values but continuing to get better every day.”

As Tom’s of Maine nears its 50th year in business, B Corp certification reflects how things have and haven’t changed at the business over time. In 2006, Colgate-Palmolive bought a majority of the business, but the company maintains a culture that is as much about helping people and the planet as it is about profit — holding tight to what the founders envisioned nearly 50 years ago.

“What has changed over 50 years is the complexity of issues,” Robinson says. “There’s an opportunity for us to continue the journey, making sure the values in place 50 years ago remain that way. The certification reflects 50 years of operating that way and a commitment to keep operating that way.”

Rubicon Global: Going Beyond Reduce, Reuse, Recycle

With a bold mission to end waste in all its forms, Rubicon Global provides software and data services to help clients manage their waste and recycling programs — and find solutions to help them avoid creating the waste in the first place.

With more than 350 employees across five offices, including its headquarters in Atlanta and core teams in New York City and San Francisco, Rubicon links clients with its network of more than 5,000 independent waste haulers.

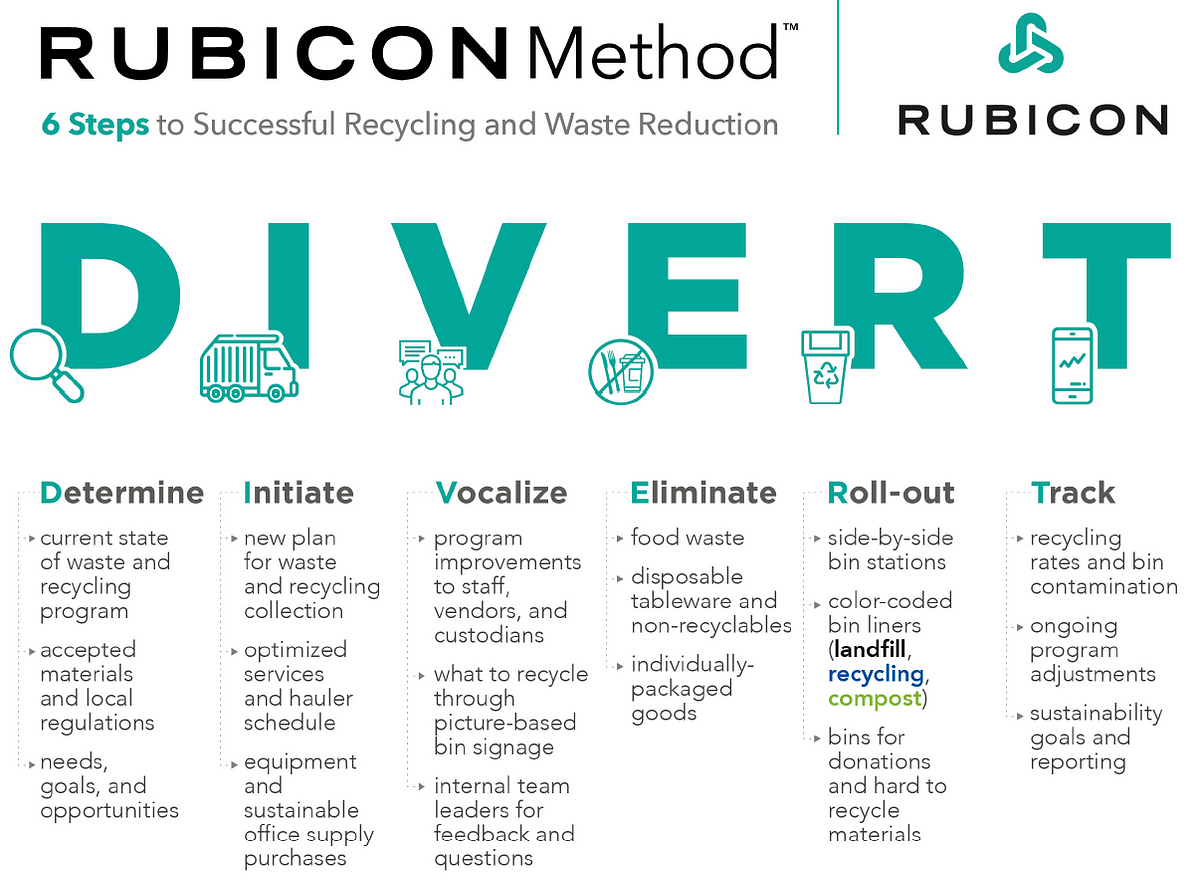

By expanding upon “reduce, reuse, recycle,” Rubicon helps clients and their employees reduce and manage their waste. That’s the inspiration for its RUBICONMethod that includes six steps to set up and maintain a business recycling program — determine, initiate, vocalize, eliminate, roll-out and track — aka DIVERT.

David Rachelson, vice president of sustainability at Rubicon Global, says the six DIVERT steps are built upon what the company has learned about reducing waste and setting up recycling programs since it was founded in 2008.

“At its core, reducing waste is a lot more complex than reducing energy or water use,” he says. “It’s much simpler to turn off a light, or use a sensor on a faucet in a restroom, than it is after lunch to figure out how to sustainably get rid of the waste someone created through a takeout meal. There’s a lot of complexity surrounding how you manage and reduce waste.”

That’s why Rubicon developed DIVERT: To remove some of that complexity and move more organizations of all sizes toward zero waste. The six steps take them through an audit, to provide a baseline by examining what’s purchased and what’s in their waste.

This isn’t your typical audit. The Rubicon team even dives into trash bins to identify waste streams, Rachelson says, which helps to inform the waste reduction plan.

“By focusing on all parts that touch the waste stream, from employees to janitorial services, we’re making sure everyone is connected and understands what can be recycled,” Rachelson says. “We really want to eliminate waste before it enters a building or facility. That involves looking at all parts of the supply chain and trying to understand how to procure in a way that reduces waste before it becomes an issue.”

A B Corp since 2012, Rubicon is working to change the typical, linear trash-to-landfill system to a circular model that creates more economic benefit while reducing waste.

“We’re working to bring a circular economy to an industry that has not experienced significant innovation with technology or the business model through which it operates,” he says. “Our goal is to reduce the amount of waste that is unsustainably managed. As a B Corp, we want to share our best practices with the world and help everyone understand how to reduce their waste.”

A Domino Effect

Clients come to Rubicon for a variety of reasons, but Rachelson says in many cases employees are driving that decision.

“They’re on the front lines and see the challenges or are the ones that get the most frustrated when it’s not done right,” he says. “Businesses are feeling pressure from employees and consumers themselves. They’re a positive influence to recycle and do it the right way.”

Once clients begin working with Rubicon, that positive influence expands beyond the business as employees see new opportunities at work and at home.

“We’ve found that once the method is in place, it’s a segue to do additional things,” Rachelson says. “They identify new waste streams that could be diverted, further educating staff around how to do it right. And ultimately we then have created a conduit of knowledgeable partners. A lot of the effort is how to create an ecosystem of recycling ambassadors at all these businesses to then help create a domino effect of promoting the right way to do it.”

Like B Corps that consider multiple stakeholders in their business practices, Rubicon’s method goes beyond a bottom-line benefit — although most clients see a cost-neutral program from the start.

“It’s really built around this mission to end waste and a belief that our business can be used not only as a vehicle for shareholder value and return, since we are a venture-backed company, but also to have a positive impact,” he says.