Since its outbreak in China in December 2019 and recognition as a pandemic by the World Health Organization (WHO) in March 2020, over 725,000 cases of Covid-19 have been confirmed in 202 countries resulting in over 34,000 deaths. The United States, with over 140,000 cases has become the latest coronavirus epicenter after China and Italy. Far from prepared, the U.S. is undergoing a dire shortage of personal protective equipment (PPE) and seeing patients die while waiting for a bed.

Desperate times call for desperate measures. In Washington State, motels are being leased and soccer fields are turning into tented triage hubs. The Javits Center in Manhattan is being repurposed as a 1,000-bed field hospital. A massive field hospital is going up in Central Park.

California is reopening previously shut hospitals, and Navy hospital ships are being deployed to New York City and L.A. The hospital situation in New Orleans, among many other cities, is so bleak, due to the influx of patients and the lack of ICU beds, it has been called a war zone.

While hospitals and healthcare workers wait impatiently for critical supplies, companies are stepping up as much as they can. Gap Inc., Apple, and Yves Saint Laurent, for instance, are making PPE such as masks, gowns, and scrubs. Companies like Estée Lauder, Louis Vuitton, Tito’s, and Pernod Ricard USA are brewing batches of hand sanitizer. Citizens are also being called on to help.

One start-up company in the U.S., Jupe Health, has recently launched another potential plan to get hospitals the emergency bed solutions they need. Co-Founders Jeff Wilson and Cameron Blizzard have teamed up with Dr. Esther Choo — researcher, physician, and Chief Medical Advisor — and Cameron Sinclair — humanitarian designer, social impact entrepreneur, executive director of Armory of Harmony, and Chief Humanitarian Advisor — along with multiple ICU and ER doctors and former employees of SpaceX/Tesla.

Modular units originally designed for housing for displaced persons are being transformed into portable health spaces for patients and healthcare workers.

Using core “off-the-shelf” technology and materials, the design begins with a patent-pending infinitely configurable chassis built into three solar/battery-powered designs: REST, an 8.5 x 13-foot rest and sleeping unit with a queen or two full beds, batteries in the base, storage, waste containers, lighting, and USB chargers; CARE, a two-platform, twice the size of REST, wellness unit with a full bathroom and simple kitchen; and PLUS, a stand-alone, PPE-ready, light version of an ICU with ventilator and connected don/doff chamber.

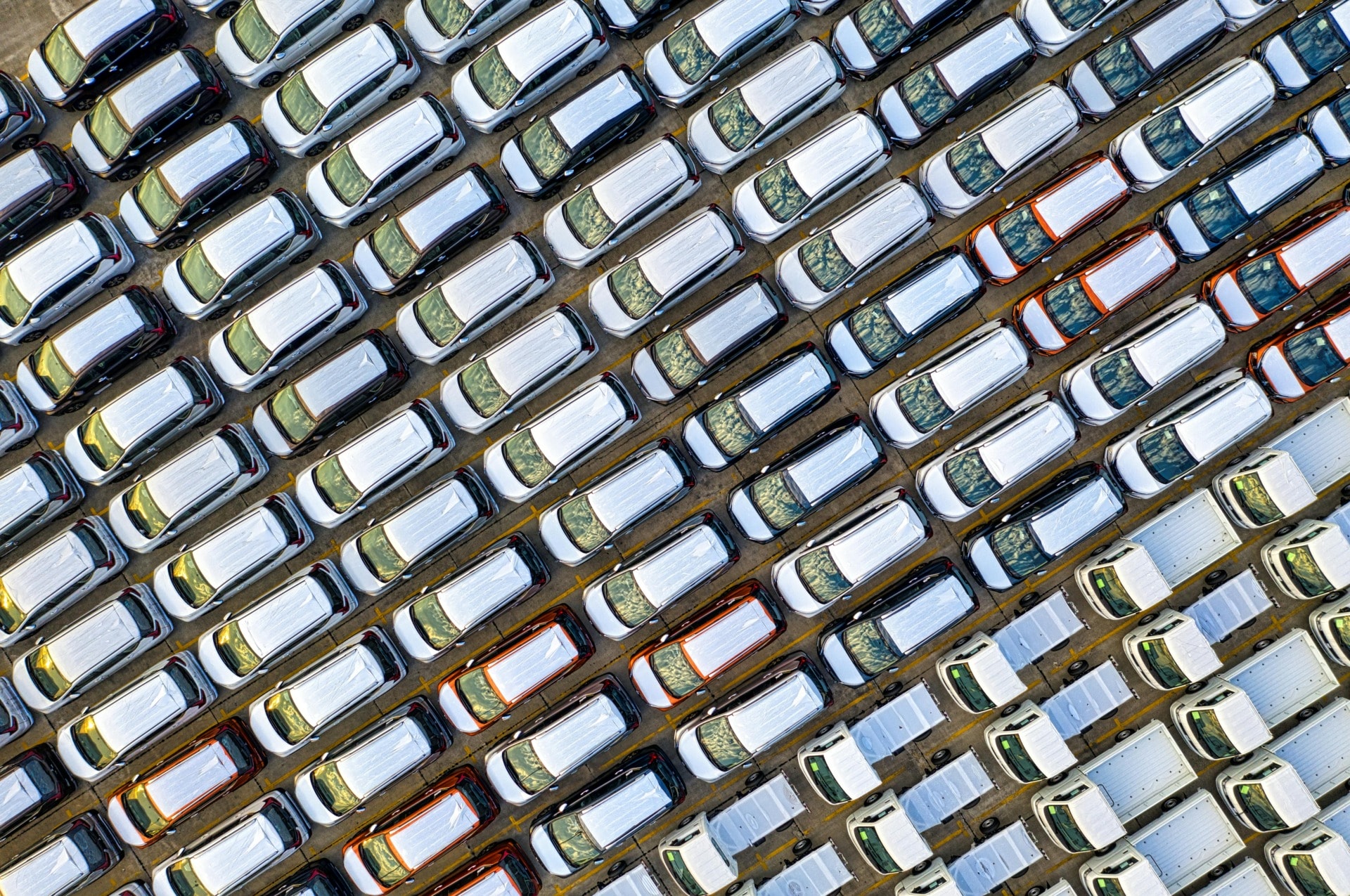

A premium-plus, stand-alone, off-grid ICU unit is also in the works. All are Wi-Fi/Network and IoT ready, and climate control systems can also be added. To transport the spaces, 24 units can be transferred at a time via standard 40-foot flatbed pulled by a pickup truck. When no longer necessary for the current Covid-19 crisis, the units can be reconfigured into new designs.

The prototype is underway in their Texas facility, with production taking place in the El Paso area.

Jupe Health is also open to working with additional housing manufacturers based on demand and is looking into international expansion through partnerships.

This and efforts by other companies and citizens are imperative. What we need right now is a global response to bring about the most immediate and sustainable solutions.

“We are in this together – and we will get through this together.”

— António Guterres, Secretary-General of the United Nations

Editor’s Note: The opinions expressed here by Impakter.com columnists are their own, not those of Impakter.com — In the Featured Photo: Jupe Container Ship with 500k Jupes — Featured Photo Credit: Jupe Health