The way we power cars is changing. Not only because electric vehicles are becoming more common, but because the technologies behind them are quietly evolving. Batteries sit at the centre of this shift. They shape how far a car can drive, how often it needs care, and how confident owners feel keeping it for years.

Solid-state batteries have emerged as one possible next step. Researchers and manufacturers could offer safer designs, longer life, and new manufacturing choices. At the same time, carmakers are making different bets, and the energy system around vehicles is changing just as fast. Together, these forces are redefining what electric mobility could look like in everyday life.

Why solid-state batteries matter for electric vehicles

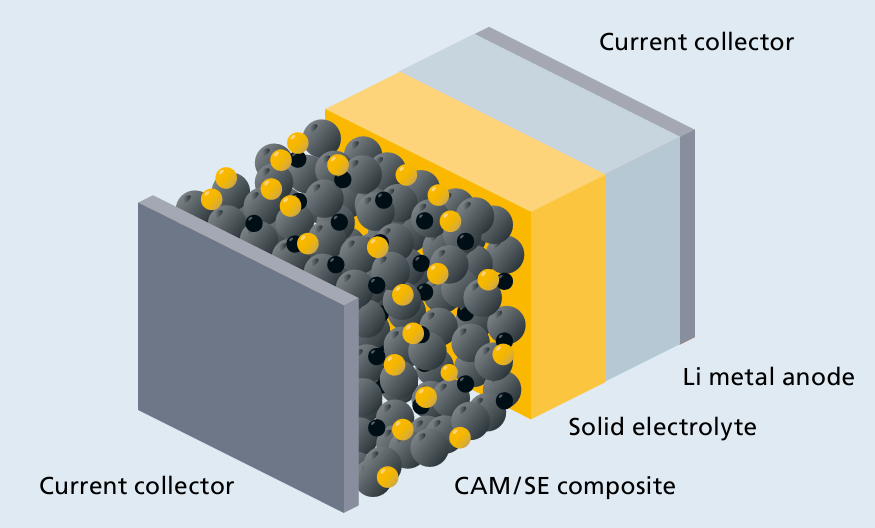

To understand why solid-state batteries matter, it helps to start with what changes inside the battery itself. Instead of relying on a liquid electrolyte like today’s lithium-ion batteries, solid-state batteries use a solid material. Battery researchers, including those behind the Solid-State Battery Roadmap developed by Fraunhofer ISI, say this design removes flammable liquids from the cell, thereby improving safety and stability at a fundamental level.

The solid structure also changes how lithium ions move within the battery, potentially enabling higher energy density and longer battery life at a time when major performance gains from conventional lithium ion designs are more difficult to deliver without sacrificing durability, safety, or cost.

Here, the relevance of solid-state batteries for electric vehicles becomes clear. They enable faster charging and higher power without increasing size. Toyota says solid electrolytes allow ions to move more efficiently and remain stable under higher voltages and temperatures, and that recent progress has improved durability and enabled development to move beyond experimentation. The focus has shifted to production, with the company targeting commercial use in battery-electric vehicles around 2027 to 2028.

Different bets: Toyota vs Tesla

From there, the question becomes less about chemistry and more about industry. Toyota’s strategy shows that the real challenge now lies in manufacturing. In its 2024 Integrated Report, the company explains that early solid-state designs struggled with durability, as repeated charging caused expansion and contraction within the cell, which damaged performance over time.

According to Toyota, these issues have now been addressed, allowing development to move toward manufacturing readiness. Solid-state cells require extremely precise and fast stacking to avoid damaging the solid electrolyte. Toyota says this cannot be done easily on existing lithium-ion production lines, which is why it is investing in new equipment and dedicated manufacturing processes.

At the same time, Tesla is taking a more cautious view. The company is not currently planning to use solid-state batteries in its cars. According to Tesla’s battery suppliers, Panasonic and CATL, the technology remains expensive and difficult to scale for large electric vehicles. They argue that solid-state batteries may be better suited to smaller applications where size and weight matter more than cost. For Tesla, which has built its strategy around lowering prices and expanding volume, that assessment shapes its technology choices. Together, these contrasting approaches show there is no single path to vehicle electrification. Each company is weighing cost, performance, and risk differently.

These different strategies reflect a shared concern about durability, cost, and long-term ownership, even as they lead companies in various technological directions. Solid-state batteries are one way manufacturers are trying to address these pressures. They are designed to last longer and operate under more demanding conditions. They support faster charging without accelerating wear. Analysts at the International Energy Agency (IEA) note that improvements in battery durability reduce the risk of degradation over time, helping build confidence in long-term ownership and lowering concerns about unexpected maintenance costs.

Related Articles

Here is a list of articles selected by our Editorial Board that have gained significant interest from the public:

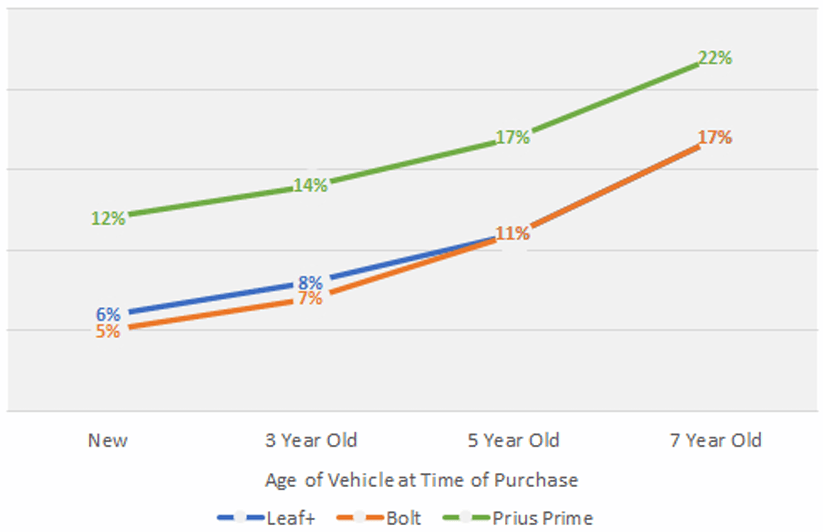

That matters because electric vehicles already start from a simpler mechanical base. According to the U.S. Department of Energy, electric motors have fewer moving parts and require fewer fluids than combustion engines, while regenerative braking reduces brake wear. These design factors translate into lower routine servicing over the vehicle’s life.

Consumer Reports has found that battery-electric vehicle owners spend about half as much on repairs and maintenance as owners of comparable petrol cars. When buyers compare vehicles based on lifetime cost rather than sticker price alone, that difference becomes easier to recognise.

Part of a broader shift in electric mobility

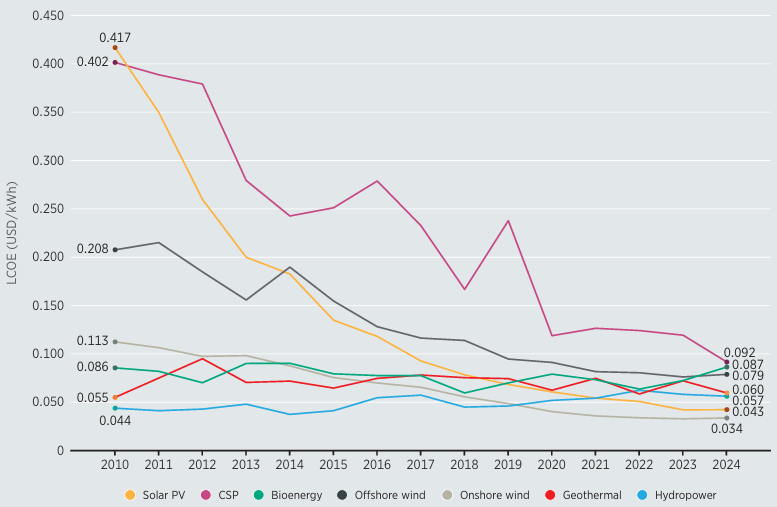

The wider energy system reinforces this trend. The International Renewable Energy Agency (IRENA) says the rapid expansion of renewable energy has reduced electricity generation costs in many regions. Cheaper electricity makes driving electric more affordable day after day, while fuel savings become more predictable. As operating costs fall, the value of a durable, long-lasting battery increases.

Grid upgrades and improved system efficiency are also accompanying the growth of renewable energy. Energy agencies note that investments in grids and storage are making charging more reliable and more accessible, supporting more frequent use and faster charging. As charging becomes easier, battery durability becomes even more critical. At the same time, cleaner power systems reduce exposure to fuel price volatility, creating a more stable environment for drivers planning long-term ownership.

Seen together, these shifts help explain why battery technology, vehicle design, and the energy system are increasingly moving in step. Advances in one area quietly raise expectations in another. As electric vehicles become easier to own, cheaper to run, and more closely linked to cleaner electricity, attention naturally turns to technologies that can last longer and perform more reliably over time. In that sense, the debate around solid-state batteries is less about picking winners and more about understanding direction.

Carmakers are responding to the same pressures in different ways. Some are pushing new battery architectures to unlock durability and performance gains, while others are refining proven technologies to keep costs down and scale up quickly. In parallel, cheaper electricity, simpler vehicle mechanics, and improving grids are reshaping what drivers expect from electric cars over time.

Solid-state batteries sit within this landscape as one response to those shifting expectations. Their significance lies not in replacing everything that came before, but in highlighting how technology, industry choices, and the energy transition are increasingly shaping electric mobility together.

Editor’s Note: The opinions expressed here by the authors are their own, not those of impakter.com — Cover Photo Credit: Tom Fisk.