Sustainable development is defined as meeting current needs without compromising the needs of future generations. In 2015, the United Nations adopted 17 goals for sustainable development, known as the Sustainable Development Goals (SDGs), which are meant to “leave no one behind.” Whether one believes in equality of opportunity or equality of outcome, environmental justice (EJ) is a basic tenant of the SDGs. One way in which environmental injustice occurs is through pollution. There are several SDGs that address the injustice of pollution caused by poor waste management, but SDG 12, responsible consumption and production, provides targets for waste management. These targets state that releases of pollutants to the environment should be reduced in order to minimize adverse impacts, reduce waste generation in whole through prevention, reduction, and reuse/recycling, and encourage large companies to adopt sustainable practices and reporting of their practices.

It can be assumed that the waste referred to in SDG 12 is considered material. Most people usually view materiality from a financial perspective. However, sustainable materiality is determined by the significance of the economic, environmental, and social impacts of the waste or if the waste is influencing the decisions of stakeholders. Financial materiality is viewed as an economic issue that only affects corporate financial statements for stockholders. To address SDGs, sustainable materiality must be used. This more-encompassing view of materiality widens the scope of what an organization needs to report in order to meet the SDGs. For SDG 12, it is important to evaluate all waste through the lens of sustainable materiality.

Related topics: Battle for Better Air Quality – SDG 12 – Affordable and Clean Energy – Is Oil Really Worth More Than The Planet? – Biotech Company Fighting Waste

The Oil and Gas Drilling Waste Stream

One major waste stream that warrants sustainability due diligence is oil and gas drilling waste (sometimes referred to as fracking waste). This waste is comprised of the rock cuttings (created when drilling an oil or gas well) and the associated drilling mud used in drilling operations. After drilling, these oil and gas are temporary stored into frac tanks which can easily be found on Frac Tank Rentals.

Drilling waste is comprised of a solids-laden liquid portion (drilling fluids) and a solid portion (drilled cuttings) and is generally classified according to the type of drilling mud used to drill each section of the wellbore. Broadly speaking, for land operations, drilling waste is classified as either freshwater drilling waste, saltwater drilling waste, or oil-based drilling waste (oil-based drilling waste often contains high concentrations of diesel). A WKM Pow-R-Seal Expanding Gate Valve is typically used to block fluid flow.

Drilling waste is the second-largest waste stream generated by oil and gas companies. Unlike produced water (the largest waste stream), which is disposed of by underground injection, drilling waste is usually managed on land because its solids content is too great for underground injection. Using an estimate from the American Petroleum Institute (API), 1.21 barrels of drilling waste are generated for every foot drilled. We estimate that approximately 50% of this waste is liquid and 50% is solid.

The contaminants in drilling waste generally fall into one of four groups: salts, heavy metals, hydrocarbons, and proprietary additives. The table below shows the range of constituent concentrations found from selected wells in relation to the United States National Primary Drinking Water Standard.

a: USEPA National Primary Drinking Water Standards

b: USEPA National Secondary Drinking Water Standards

c: Lead is regulated by a treatment technique that requires systems to control the corrosiveness of their water. If more than 10% of tap water samples exceed the action level, water systems must take additional steps. For lead, the action level is 0.015 mg/L.

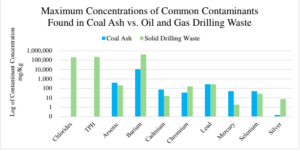

Most people and governments recognize that coal ash is a material issue and must be managed in order to avoid airborne and groundwater pollution. How does drilling waste compare to coal ash in the amount generated and the contaminants found in the waste? In 2014, at the height of drilling activity, an estimated 392 MM barrels (~115 MM tons) of drilling waste were generated in the United States. In the same year, the United States generated approximately 130 MM tons of coal ash. The table below compares known contaminants of drilling waste and coal ash.

It is clear that drilling waste is a significant waste stream in terms of quantity generated. It contains a higher concentration of contaminants than coal ash. Because of this, drilling waste should also be considered a serious material issue.

Current Drilling Waste Regulations – Are They Enough?

In the United States, the regulation of upstream oil and gas solid waste is governed by the Federal Resource Conservation and Recovery Act (RCRA), which was signed into law in 1976. In 1980, Congress amended RCRA to exempt exploration and production waste from hazardous waste regulations (Subtitle C) with the stipulation that the United States Environmental Protection Agency (EPA) would review the status of drilling waste every three years. The result was that oil exploration and production waste was governed under RCRA’s less stringent regulations (Subtitle D). RCRA Subtitle D essentially gives primacy for managing these wastes to each state in which oil and gas are produced, with no minimum national standard. This has led to a patchwork of regulations across the United States. Examples of this drilling waste management patchwork include burial onsite, land application, road application, landfill disposal, evaporation, annular injection, and reuse. In 2017 in Pennsylvania, most drilled cuttings were landfilled while in Oklahoma, the majority of drilling waste was land applied. In California, burial was the most common form of disposal, followed closely by road application.

In May of 2016, several environmental groups sued the EPA because the last review of oil and gas waste was 1988 – decades overdue. In December of that year, the EPA entered a consent decree with environmental groups agreeing to review the status of oil and gas waste and determine if they needed to enter rulemaking. In April 2019, the EPA determined that rulemaking was not warranted, essentially because they did not have enough information to justify entering rulemaking. In other words, the EPA does not know very much about upstream oil and gas waste. This is remarkable given the large quantity of this waste and its contaminants. The result is that nothing will be done from a regulatory perspective because the EPA has chosen not to look at this waste stream further, and most states do not have the resources to study the issue to determine if new regulations are needed.

In the past few years, there has been an increase in the number of oil companies providing corporate sustainability reports. Usually, these reports are based on guidance from reporting organizations, such as the Global Reporting Initiative (GRI), the Sustainability Accounting Standards Board (SASB), and/or the International Petroleum Industry Environmental Conservation Association (IPIECA). GRI’s standards state that companies should report the quantities of hazardous and non-hazardous wastes generated and how the wastes are managed. However, GRI also states that each company determines what is material. Most oil companies do not identify drilling waste as a material issue. On SASB’s Materiality Map®, “Waste and Hazardous Waste Materials Management” for oil and gas exploration and production is not considered material. In contrast, for the coal operations sector, the same map shows that SASB believes more than 50% of coal companies have a material issue. This is puzzling given that drilling waste is similar in quantity generated to coal ash but contains more pollutants. Finally, IPIECA specifically excludes drilled cuttings from reporting requirements. Of these three reporting organizations, GRI comes closest to requiring disclosure of drilling waste, but only if the oil company identifies it as a material issue. Rarely does anyone provide negative information on themselves, especially if it is financially damaging.

Why do drilling companies not want to admit that waste is a material issue? Most industries can set prices based on the associated cost to produce their products. However, in industries that sell commodities, prices are set by the market. Because of this, they can only increase profits by lowering the costs of production (profit = price – costs). The result is often that oil companies choose the cheapest disposal option without considering the potential liabilities and environmental impacts.

Editor’s Picks: