This article is part of an editorial collaboration with BCorporation. The BCorp Series can be found here. The original publication can be found here.

With a Healthy Planet in Mind, Companies Put Environment Among Primary Stakeholders

Certified B Corporations aren’t waiting for government action to start addressing the changes in our climate. The B Impact Assessment, used to certify B Corps, helps businesses measure and manage their environmental and social impact.

B Impact Assessment results show that B Corps outperform thousands of other businesses that have taken the assessment by 16% on climate mitigation efforts, such as using low-impact renewable energy, adopting energy efficiency practices, monitoring and managing greenhouse gas emissions and carbon intensity, and providing products or services that support cleaner burning or renewable energy.

We asked a few B Corps that excel at climate change mitigation about their Earth-friendly business practices and products. Here’s what they shared.

Green Mountain Power

Green Mountain Power is an investor-owned electric generation and distribution utility based in Colchester, Vermont.

Green Mountain Power is using energy as a force for good by supplying cost-effective, reliable power to about 75% of Vermont, while helping customers cut carbon to fight climate change. There is an urgency to act to reduce carbon emissions, and we offer many programs and opportunities that make it simple and empower customers to take action about how they use energy.

We offer customers innovative, industry-leading products and services, like the Powerwall home battery. We also offer incentives to help customers buy home batteries from other providers and drive electric vehicles, which help reduce their carbon footprints and stay comfortable.

Green Mountain Power has programs to encourage customers to switch to electric vehicles.

The GMP energy supply is 90% carbon free and 60% renewable. We operate wind, solar and hydro facilities across the region.

GMP is a leader in using solar arrays combined with energy storage to cut carbon and costs for all customers. We have two solar and storage installations and plan to construct three more. Our innovative work with energy storage has already saved customers more than $500,000.

Within GMP we are also taking on climate change by tracking company carbon emissions internally in a public way, and creating incentives and education opportunities to encourage all employees to reduce carbon every day. Some examples: We incentivize video conferencing and carpooling. Our company fleet has hybrids and EVs. We buy local foods, products and services as much as possible. Groundskeeping at our offices is electric, with much lower emissions than traditional fossil fuel mowers and trimmers. We are also in the process of installing a solar canopy over our parking lot at our company headquarters.

People Against Dirty built its South Side Soapbox factory in Chicago as the industry’s first LEED-platinum certified plant.

People Against Dirty

People Against Dirty, based in San Francisco, is a home and personal care company made up of two brands: method and Ecover.

As a B Corp, People Against Dirty looks across everything that we do to identify how we can eliminate carbon. We always start with our products. Like most product companies, our Scope 3 emissions — in our case, the carbon associated with producing our bottles and formulas — accounts for most of our carbon footprint. The first step is using a majority of plant-based, renewable ingredients for our formulas.

Next we look at our bottles. Most of our bottles contain 100% post-consumer recycled (PCR) plastic, and we’re heavily invested in adding PCR into our pumps and sprays. PCR is beneficial from a carbon standpoint because using PCR plastic has about a 70% lower carbon footprint than virgin plastic. We also offer refills for most product types, which has a 80–82% lower energy and plastic footprint than using individual bottles and translates directly into carbon savings.

The South Side Soapbox has on-site solar arrays and wind turbines.

But our carbon initiatives are not just about our products — we also look at how they’re made. Our factory, the South Side Soapbox in Chicago, uses onsite renewable energy from wind turbine and solar panels. Remaining energy needs come from renewable power supplied through the utility.

We were also very intentional about the factory location to take transportation miles out of our supply chain; we use integrated manufacturing, bringing our bottle manufacturer, filling operation, decoration and warehousing under one roof to eliminate carbon. We shortened the distance that a bottle travels during production from 1,000 miles to 1,000 feet, allowing us to operate more quickly and flexibly.

We also built the factory in an urban location to create jobs closer to where people live to cut miles traveled; most of our movers and makers come from the local five ZIP codes in the south side, which is also a part of our mission to bring new, green jobs to an under-resourced community. We used LEED to inform how we could make the most energy and carbon efficient factory possible, and today the Soapbox is the only LEED-Platinum certified factory in our industry.

Klean Kanteen

Klean Kanteen is a family-owned B Corp based in Chico, California, that produces and sells BPA-free, stainless steel drinkware and food containers.

At Klean Kanteen, we recognize current climate patterns are being influenced in their rate of change and intensity by an increase in greenhouse gas (GHG) emissions from human activities. When it comes to running a business in a global community that is seeking to limit negative impacts of climate change, we aim to operate with a low emissions intensity while still meeting the everyday energy demand of our business. To that end, we take an approach that involves identification of Klean’s emission sources across the product life cycle, measurement and active communication of emissions risks and opportunities, adoption of renewable energy, conservation, and mitigation. Below are some examples of Klean’s climate strategy in action.

We measure and actively communicate internally about energy use and GHG emissions connected to Scope 1, 2, and 3 activities (direct emissions, indirect emissions, and those related to the company’s activities).

We take action to conserve energy at Klean’s headquarters. Windows were strategically installed throughout the building to provide plenty of natural lighting without impacting heat load. Thermostats operate at conservative but still comfortable settings year-round. LEDs and efficient office equipment are the norm.

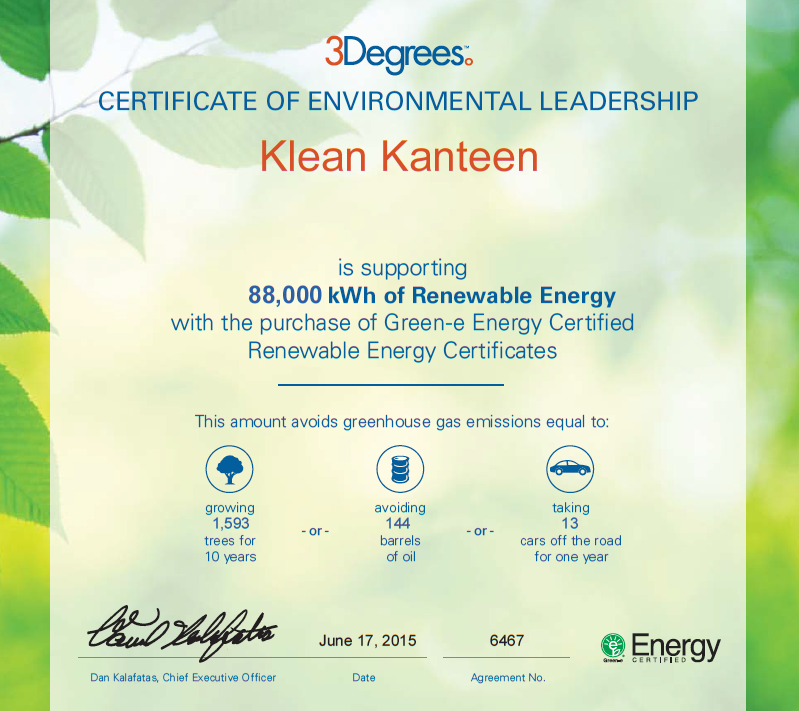

Between 2009 and 2017, Klean Kanteen purchased renewable energy credits equal to all of its facility electricity use.

As a starting point we have looked to renewable energy credits (RECs) and carbon offsets to mitigate our emissions while we work out how best to directly avoid emissions. Investments in RECs and offsets help subsidize emissions-reducing projects like wind energy and forest conservation. Between 2009 and 2017, Klean purchased RECs equivalent to 100% of its facility electricity use. In addition, Klean started purchasing carbon offsets in 2010 to neutralize emissions related to shipping product from our online store. Over the past nine years these offsets have added up to 6,600 metric tons of GHG emissions avoided.

In 2017, Klean Kanteen began tackling its GHG emissions by installing 216 high-efficiency solar panels with the ability to generate 141,323 kW of power on the roof of our headquarters. Any extra power generated by the solar array is fed back into the energy grid for others to use. Our 2018 GHG emissions from facility electricity use dropped 66% compared to the previous year, and our emissions intensity also dropped.

We use life cycle assessment to identify the emissions hotspots of Klean products. Information from life cycle assessment models coupled with energy and emissions measurements are provided to Klean’s management team to equip them with information they need to make emissions-conscious business decisions.

We advocate for progressive climate and renewable energy policies, and signed onto the We Are Still In campaign in 2017 to demonstrate collective commitment to the Paris Climate Agreement from businesses, universities, nonprofits, and government to achieving aggressive global emissions reductions.