As more and more countries around the world develop a middle class, rising incomes have led to rising demand for protein consumption, including seafood. The FAO’s most recent State of World Fisheries and Aquaculture Report from 2016 noted that global per capita fish consumption had risen to above 20 kilograms for the first time, with fish providing 6.7% of all protein consumed by humans. One of the sources of supply to meet this demand is aquaculture, also known as “fish farming”, and that is where Knipbio comes into play.

Aquaculture normally has its set of benefits, like ensuring consistent fish supply and stimulating economies. However, it’s also a double-edged sword; farmed fish requires food, which often takes the form of other wild fish, which in turn ultimately contributes to over-fishing elsewhere.

In the face of this conundrum, Knipbio has looked at the field of aquaculture differently. The Massachusetts-based company has developed fish feed strains derived not from other fish, but rather from proteins developed through biotechnology, which holds the promise of large-scale production with fewer resources than ever before. I talked to co-founder and CEO Larry Feinberg, PhD, to learn more about Knipbio’s approach to aquaculture, the biotechnology behind its products, and some of its potential applications.

How did Knipbio originally get started?

Larry Feinberg: I was working for a cellulose biofuels company, and at the time there was this thing called fracking coming online. By then it was becoming pretty obvious that there was a market desire for low-carbon biofuels. Reading the writing on the wall, I started thinking about other big problems out there to try and solve.

I’m actually a pescatarian by dietary preference, and I have been for many years. Combined with being a fermentation scientist by training as well as my passion and interest around the ocean, I started doing some research. I interviewed some folks, one of whom was a professor at Harvard, and we hammered out some of the very initial concepts at that time. We pulled some strains out of his lab, did some really primitive fermentations in my barn about 25-30 miles west of campus, brought that protein down to the New England Aquarium, and ran some of the very first trials for those guys. It was like checking to see if the dog ate the dog food, although in this case it was did the fish eat the fish food.

In the Photo: Knipbio fish feed. Photo Credit: Knipbio.

In the Photo: Knipbio fish feed. Photo Credit: Knipbio.

Knipbio’s purpose is to “enable sustainable aquaculture”, what does that mean to you and Knipbio?

LF: Sustainable to me is a triple bottom line that includes people, profit, and planet. You really can’t have one without the other. Having something that is not cost-effective but is very in tune with the environment is not going to go anywhere. We have to combine those three to really serve people, who are ultimately the ones who hold the dollars and move things around. It’s a real magical balance, but that’s what sustainable means to me.

Specifically the world is demanding more and more fish protein every single day, yet our oceans have not had an increase in productivity over the last 25 years. It’s been flat or even decreasing. The question is how do we match these things up, and we’re really going to have to look in different corners of the globe. Taking more fish out of the sea to feed fish is not an option. Also, we may not be that far from of running out of acres to be planted for terrestrial purposes. We really may be converging up on the limits of multiple dimensions.

So what’s something that’s different? How about brewing protein in a vessel, where you literally need 1/1000th the amount of acreage for a fermentation facility than you do a soybean farm. Doing more with less definitely has to be and continues to be the way towards the future. That’s what I mean by sustainability.

In the Photo: A fermentation device. Photo Credit: Knipbio.

In the Photo: A fermentation device. Photo Credit: Knipbio.

Knipbio also touts its use of biotechnology, could you describe that technology in greater detail?

LF: In some ways we combine several features that are individually available. Sources of protein, sources of pre-biotic compounds to make the micro-biome more robust, as well as some of these really strong antioxidants that are important for coloring. Having this trifecta of ingredients is one unique feature.

But we can also turn dials up and down, and we’ve shown pretty consistently over the last couple of years that we can affect the way carbon flows within our organisms to make more of something or less of something. By using biotechnology, we can really tailor what the ultimate product composition is for the needs of a feed formulator or a producer for shrimp or salmon for example. Unlike poultry or cattle or swine, which in each case is essentially one species with a bunch of different breeds, aquaculture is 600 species, of which 50 of them are seaweed! So we need to be able to tailor nutrition, because there’s no way groupers have the same nutritional demands as shrimp. These things are going to be very different from each other. The idea of understanding nutrition in this industry is really very young, 50 years tops. Just looking at ingredients is going to be important, but also having that flexibility and versatility is really critical.

RELATED ARTICLES:

![]() Healthy Oceans: The Cornerstone for A Sustainable Future

Healthy Oceans: The Cornerstone for A Sustainable Future

by Inger Andersen

![]() Why Deep Dive Fishing Needs Safer Standards

Why Deep Dive Fishing Needs Safer Standards

by Festus Akinnifesi

![]() Farming in Water: The Challenges of Aquaculture

Farming in Water: The Challenges of Aquaculture

by Claude Forthomme

I would imagine that there are many potential applications for your products, so who uses Knipbio currently?

LF: We’ve had some collaborations with academic labs and published some papers, with a second manuscript that’s in review coming out soon. We’ve also worked with government labs like the USDA. In addition, we’re in commercial trials with feed manufacturers, both large and medium-sized firms. There are also the growers, some of whom are integrated and making their own feed, while others aren’t but still have a very strong pressure to understand their animals’ nutrition and performance. Feed represents at least 50% of their ongoing costs, so they care. Broadly speaking those are the categories of people we’re working with.

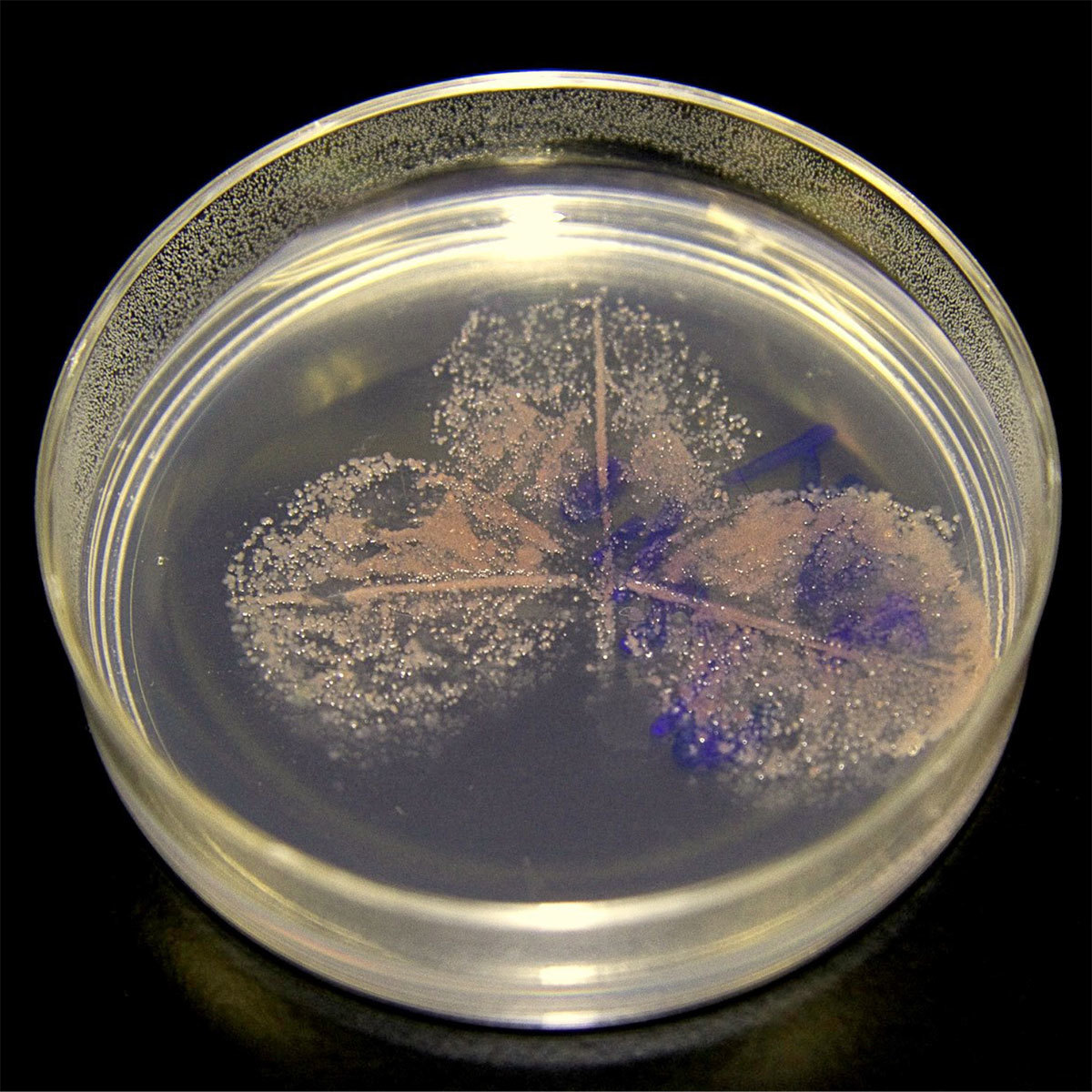

In the Photo: A leaf symbiont. Photo Credit: Knipbio.

In the Photo: A leaf symbiont. Photo Credit: Knipbio.

What do you personally see as the future of Knipbio?

LF: The past isn’t necessarily any indicator for the future, but I’ll start with that. We’ve made a lot of progress in really just a few years. We’re building out the team and we have more capabilities every year, every month even. When I look back to where we were, from the barn to where we are today, it’s accelerated in terms of our rate of development. We’re building more and more strains that are being tested with more frequency, so we can really iterate our development. Similar to how a software firm can do product development, we can think about cycles and shortening them.

I also see us having this platform to build off of to make several different nutritional solutions, starting with the same material, organisms, and fermentation equipment but having these different lineages, like juvenile feed first, then “puppy chow”, then “senior chow”.

In the Photo: Knipbio fish feed. Photo Credit:

In the Photo: Knipbio fish feed. Photo Credit:  In the Photo: A fermentation device. Photo Credit:

In the Photo: A fermentation device. Photo Credit:  In the Photo: A leaf symbiont. Photo Credit:

In the Photo: A leaf symbiont. Photo Credit: