Much has been done in the 3D printing field this past decade, but this market has often been criticized for a lack of industrial outputs due to the market being too young. Biobots was created in August 2014 with the aim to be “the future of regenerative medicine”: to create a desktop 3D printer that builds functional three dimensional living tissue.

So far, the two founders Ricky Solorzano and Danny Cabrera seem to be on the way to achieve this goal. The company raised $1.5M in one year, now has eight employees and the Biobot 1 is getting used by biotechnology researchers all around the globe. Most of all, the two Upenn (University of Pennsylvania) alumni are building a community of users through partnerships and an interesting development strategy. But, as impressive as this innovation is, it brings ethical concerns, considering that their creation enables one to digitally build living systems.

That is why we wanted to have a chat with Danny Cabrera, from the tales of their success story to the vision they wish to bring to modern biology.

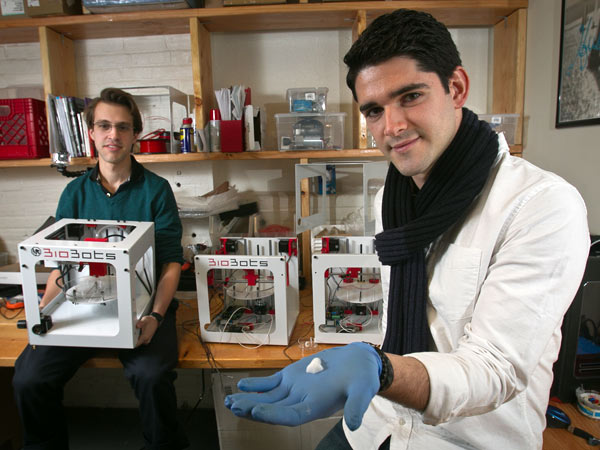

In the Photo from Right to Left: Ricky Solorzano and Danny Cabrera, co-founders of Biobots

Q. How did you meet Ricky Solorzano and what made you work together?

Ricky and I were both students at Upenn. I was working on computer science mostly and he was focused on tissue engineering, fabricating blood vessels through more ‘traditional’ technology. What happened is that we had the same mentor and advisor, who was deeply involved in the open-source 3D printing community, innovating on his own. He was actually making 3D printed candies at the time, but it didn’t take him long to start using this technology to build networks of blood vessels, injecting sugar in those channels and then replacing it by nutrients to keep the cells alive. I started getting involved at that point, focusing on the software side of it.

Related articles: “SONNY VU: THE MISFIT RENAISSANCE MAN” by ELEANOR KAVANGH BROWN

“TEACHING GIRLS TO CODE IN STYLE: JEWELBOTS” by COURTNEY CARTER

Q. How did you manage to build the first prototypes? What resources did you use?

We actually built the first prototypes in a dorm room, here, in Philadelphia. On top of a bar [laughs]. I was going to do a Ph.D. and Ricky was supposed to enter Medical school but we decided to give it a shot and see if we could get some cash to fuel the project. And we did, through accelerators and seed capital.

We then launched a program and provided beta versions of our machine to top researchers all over the world: Australia, US, Europe, Central America…

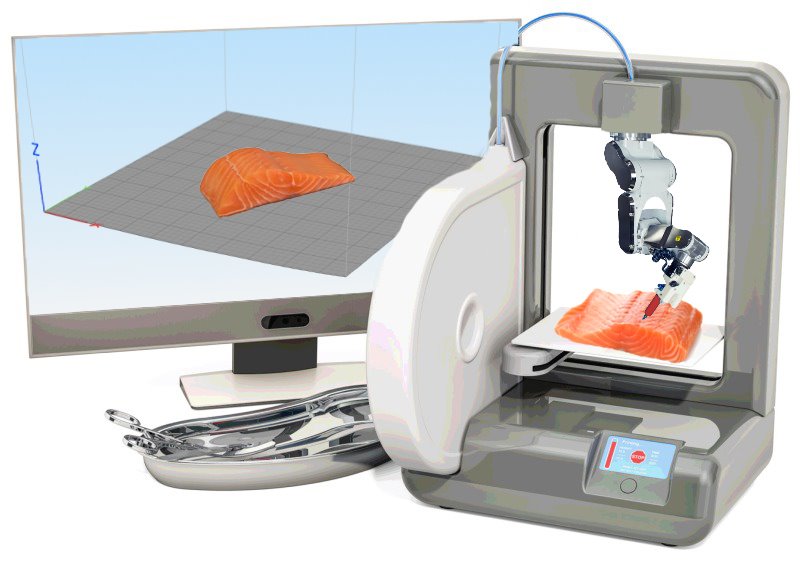

In the Photo: Biobot 1 in a lab facility

In the Photo: Biobot 1 in a lab facility

Q. You cut the price of your product in half for researchers, what is the idea behind this?

It started with the beta version: we thought that we should provide an easily affordable tool to researchers and involve them almost as partners. Therefore, they would help us understand their needs and make our technology progress. We are still thinking how we are going to use this community in the future but it has been extremely valuable.

Q. For what purposes do your customers use the Biobot 1 for now?

A part of the uses of Biobot concerns tumor clinical tests. Researchers build tumors with patient’s living cells to have a personalized approach of the disease rather than tackling cancer generally. We also have a large group of scientists who are interested in more complex structures: the ‘holy grail’ in this field is achieving to build vascular tissues, which involve a very large amount of cells. Simply put, the most groundbreaking outcome would be to print entire organs.

Q. What would you say makes Biobots stand out?

It’s the idea that you can have digital tools to design living systems. The Biobot enables you to handle the whole process digitally, reducing the risk involved by human manipulation.

In the Photo: Van Gogh’s ear made with Biobot 1 3D printer

In the Photo: Van Gogh’s ear made with Biobot 1 3D printer

Q. You grew up to eight employees in one year, what are the next steps of growth?

Yes, the idea is to double over again by this time next year. We keep hitting all of our sales milestones and it seems that we built a very sticky product, which people have a great need to use. This market is huge, and I must say that being one of the first players in the game is an advantage. But more than that, it helps us learn what the future of biology needs to look like, because we are making something that has never been done before.

Q. Indeed, your technology seems to bring new horizons to biotechnologies. There is much debate about the usage of artificial tissues, cells and appendages. Really simply: how do you feel personally about what you are creating?

What we are creating is a device that enables people to layer stuff on top of each other and gain control digitally over biology. The general consideration of our work is that we would open some kind of ‘Pandora box’ and see what happens. The reality is that the technology is too primitive: nobody has figured out how to print something that could go into a human being and work. The possibilities in terms of disease curing that our product bring are amazing and that’s what motivates us develop it.

In the Photo: A close-up view of the Biogel used in the 3D printing

In the Photo: A close-up view of the Biogel used in the 3D printing

Q. Are you concerned by the misuse of Biobot technology?

I guess that it’s a problem concerning every new technology. The internet allow us to find the right information that we need, work to find solutions to global issues and even make this interview. Now, it is also used by terrorist groups to organize attacks in all parts of the world. For every tool, there are pros and cons; we build Biobots focusing on the positive outcomes.

For more information, check out Biobot’s blog