Last February, I got the chance to visit a sustainability conference in a small town named Ukhrul in the Manipur state of India. This state is in the north-eastern part of the country, and it is well known for its hilly bamboo artwork. One of the most eye-catching showpieces at this conference was a furniture set made from discarded tires. It was truly a nice confluence of art and functionality. Something you wouldn’t mind keeping in your living room, not just for the heck of being environmentally conscious, but also for its worth. The most Indian question to ask was, “How much is the price?” It was priced at slightly less than $1000. In the Indian market, a product of similar worth can be available at 1/5th of that price. After a little chat with the maker, I easily sensed that he was struggling to sell his work. At that point, I was fortunate enough to connect him to a few automobile showrooms who then bought his work (but with slight hesitation).

Integrated Waste Management Systems

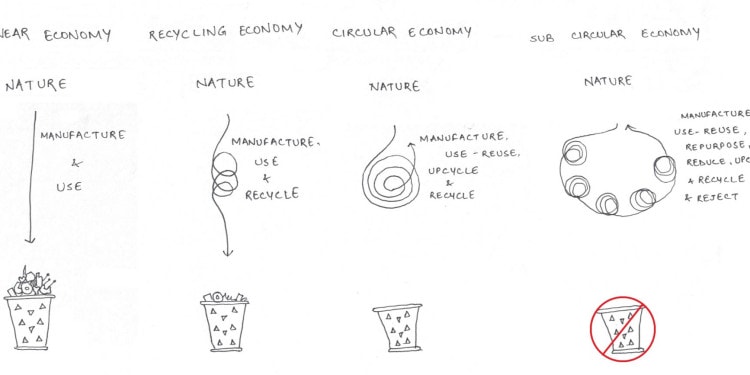

Isn’t this the main problem with managing waste? Waste warriors around the world are struggling to find a market for the end product of their respective processings. My first startup, which was into decentralized composting, was facing a similar problem. There were no good markets for the compost, and, given that chemical fertilizers in India are highly subsidized, the situation was even worse. I parted ways with this startup to focus on integrated waste management systems. I came up with a system that I believe fits a “super circular” economic model. The system suggests that, instead of composting shredded organic waste, waste should be fed to a nearby biogas unit. The biogas generated could then be used to run the vehicles and equipment used to manage the waste again. This reduces the energy requirement of waste management and reduces the marketing burden for the end product. I was fortunate enough to present this system at the Asia Clean Energy Forum in Manila in June earlier this year.

There are multiple examples of this basic tenet wherein we manage waste with waste itself. Tetra packaging cartons can be turned into plywood like sheets, but people usually avoid using them because of aesthetics. Recently, a local train station in Mumbai used these sheets to make dustbins. Undoubtedly, these dustbins made from waste appeal both aesthetically and ergonomically.

Waste management can be as simple as making dustbin liners from newspapers. We need liner on a day-to-day basis, and newspapers are a daily member of many households. This also curbs the creation of single-use plastic. This idea can be extended to bio-degradable waste as well. For example, consider making a multipurpose garbage enzyme to clean your home.  f you think that there’s no more hope for your trash to be recycled, then just make sure that you don’t litter anywhere.

f you think that there’s no more hope for your trash to be recycled, then just make sure that you don’t litter anywhere.

In the Photo: Newspaper Bin Liner. Photo Credit: Girls Going Green.

Activity: Create Your Bio-Enzyme Cleaner

The process of making a garbage enzyme (bio-enzyme) cleaner from citrus fruit peels is very simple. Bio-enzymes are created from the catalytic fermentation of biopolymers in an aqueous medium. They can easily cater to a household’s cleaning agent requirement.

Related topics: CuanTec – The Biotech Company Fighting Against Waste – Food Waste – Sustainable Consumption and Production – A Truly Circular Economy

To create your own bio-enzyme cleaner:

- Tear fruit peels into small pieces of less than an inch dimension. The smaller the pieces, the better.

- Weigh the fruit peels and put them in a plastic container.

- Add jaggery and water in a ratio of 1:3:10 of jaggery, peels, and water. respectively. You can add a pinch of fresh yeast if jaggery is not available. Use one pinch per 100 grams of peel.

- Close the container and release the air twice a day for a week. You can also let the cover be slightly open to avoid bursting the container.

- Shake the container regularly. The formation of a white layer on the surface is normal.

Editor’s Picks:

“Will we ever solve the plastics problem?”

“Will we ever solve the plastics problem?”

“Hungry for data, starving the world”

“Hungry for data, starving the world”

Tips

As mentioned in point 4, fermentation evolves gases, so I recommend not using a glass container. Containers with large openings should also be avoided. The ideal container would be a plastic bottle or candy jar.

A darker colored enzyme implies a stronger cleaning property. It can be used directly or diluted with water depending upon the strength achieved. I recommend having a patch test before use. Since the liquid is natural acid, it rarely causes damage, but it should be avoided on polished wood and marble work.

Bio-enzyme cleaners also don’t have an expiry; they get better with time. I suggest using them after 3 months of fermentation. Any leftover pulp can be ground into a paste and be used to clean utensils.

Check out my TedTalk to learn more about a “Super Circular Economy” and bio-enzymes: “Can waste manage waste? | Gaurav Gupta | TEDxYouth.”

Cover Photo Credit: Gaurav Gupta.