For decades, the construction industry maintained an almost predictable rhythm. Design work was done by hand, calculations for materials were done manually, and the process relied mostly on experience and gut instinct. All of this changed because the construction environment in the current day and age demands an entirely different degree of accuracy.

The construction industry is undergoing a transformative period in which the best and brightest in the business are embracing innovative digital intelligence to enhance their own acumen. Construction has reached a new frontier where intelligence, in the form of process solutions, results in reduced risks and minimized waste in the fast-paced construction project environment of today.

This change is much more than the latest and greatest in technology. It’s how the construction process of planning, collaborating, and performing each and every phase of construction is transformed and how the construction teams are able to unlock the efficiency in the entire process that a decade ago was impossible to attain in the construction process.

Precision Planning and the Basis for Smarter Building

Every successful project has a strong basis in pre-construction planning. The traditional process involved a lot of work in measurement, turning pages on drawings, and managing continuous revisions. Just a slight inaccuracy resulted in costly delays and budget impacts.

With modern digital process workflows, estimators and project planners are now able to refine their early-stage calculations to an incredible level of detail and accuracy. Gone are the days of random notes and hand-drafted plans. Today, construction assessment teams have access to project-wide data in real time, enabling decisions based on the best possible insight into resource and project requirements.

More refined planning leads to reduced risk and a more reliable roadmap. When the foundational estimates are properly aligned, the entire life cycle of a project runs more smoothly.

Opportunity in Streamlined Estimating and Quantity Analysis

Estimators are burdened with the responsibility of projecting what a project truly requires. Every pipe, beam, tile, and fitting must be measured and quantified, and in rapidly changing markets, a small margin of error can determine whether a bid is profitable or not.

Digital estimating processes simplify this work by eliminating the need for fully manual measurements and instead offering structured, graphical workflows. Comparing multiple drawing versions, reviewing past calculations, and working under tight deadlines becomes far more manageable without sacrificing precision.

At the center of this shift is automated takeoff. Instead of measuring each component manually, sophisticated tools allow estimators to derive quantities directly from the plans. This dramatically reduces the time spent on repetitive measuring and provides a level of accuracy that manual methods rarely achieve.

It is within this context that a subtle and natural integration occurs seamlessly. Many companies have come to depend on solutions such as STACK takeoff software to enhance their quantity measurements, ensuring that early data is complete and consistent before preparing proposals for clients. The estimating process becomes more efficient while the expertise of the professionals remains central in an industry where accuracy is paramount.

Coordination and Communications to Keep the Projects Moving

Even the best planning fails without effective communication. Construction projects involve numerous contributors—architects, contractors, subcontractors, suppliers—and each relies on timely updates to stay productive and on schedule.

Modern coordination processes address one of the industry’s long-standing issues: fragmented communication. When decisions, revisions, and documents are scattered across emails, texts, and spreadsheets, misunderstandings become unavoidable.

Centralized information systems allow project teams to synchronize updates instantly. Revised drawings reach the field without delay. RFIs move more efficiently. Subcontractors know exactly when their crews are needed. Problems are identified early and resolved before they escalate into costly rework.

This fluid communication benefits internal teams and strengthens client relationships. Owners appreciate transparency and consistent updates, and teams avoid the confusion that often slows project schedules.

More Effective Material Management to Control Costs

Materials account for a major portion of any construction budget. Estimating errors or poor planning can quickly lead to lost profit. Late orders, excessive inventory, and unexpected supply chain issues are daily challenges in the industry.

A more organized approach to material management helps teams accurately forecast and order what they need. Instead of scrambling last-minute, procurement teams know precisely what materials to order and when to place those orders.

Accurate early takeoff data is essential in this area, ensuring materials match between estimate and purchase order. Coupled with stronger planning, teams can avoid the pitfalls of overordering “just in case” or rushing to source items when it’s already too late.

Enhancing Jobsite Efficiency Through Organized Execution

Once the teams are on-site, well-structured processes become the foundation of an efficient jobsite. Without clear direction, jobsite operations can quickly descend into repeated work, misplaced tools, missed steps, or poorly sequenced tasks.

Jobsite efficiency improves when crews have consistent instructions, updated drawings, and reliable coordination. Organized workflows eliminate delays and reduce downtime by ensuring each trade knows exactly when and where to work.

Digital field documentation is another important element. Daily logs, site photos, and progress updates can be completed quickly, keeping management informed without pulling workers away from essential tasks. When weather disruptions, design changes, or material shortages occur, teams can adapt immediately because the information they rely on is always current.

Risk Reduction and Quality Assurance in All Stages

Risk is an unavoidable part of construction, but well-defined processes make those risks more predictable and manageable. Whether related to safety, regulatory compliance, or structural accuracy, construction requires constant oversight.

Modern workflows help project teams detect potential issues early through consistent documentation, real-time updates, and reliable plan version control. When everyone works from the same information, errors decrease and quality standards become far easier to maintain.

Efficient planning and estimating reduce financial surprises. Strong communication prevents unnecessary rework. Accurate material forecasting guards against shortages. Collectively, these improvements create a more stable foundation in an industry that is naturally complex and fast-moving.

The construction sector continues to evolve as demands rise for speed, sustainability, and cost effectiveness. The most successful firms will be those that adopt smarter processes as long-term strategies rather than temporary upgrades. Even small improvements can significantly impact the competitiveness of both the project and the company.

Whether it involves improving estimates, enhancing communication, strengthening jobsite organization, or fine-tuning risk management, construction intelligence offers a compounding advantage. It empowers teams to make better decisions and consistently deliver high-quality work.

The future of construction is not only about building faster—it’s about building smarter. As workflows become more integrated, precise, and collaborative, the industry is moving toward a reality where accuracy and efficiency are not exceptions but expectations.

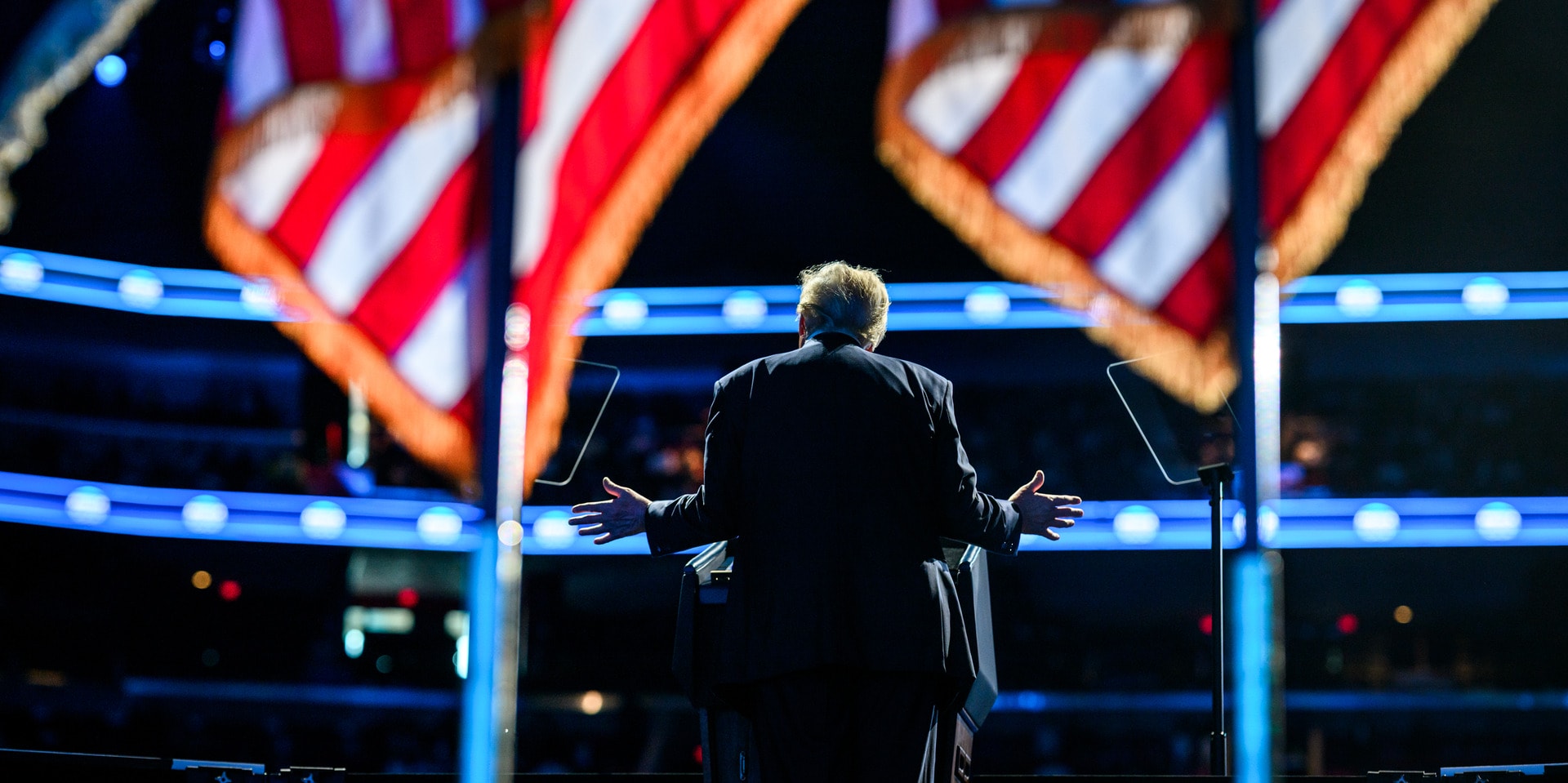

Editor’s Note: The opinions expressed here by the authors are their own, not those of Impakter.com — In the Cover Photo: Deploying construction intelligence. Cover Photo Credit: : ijeab