During the last century, Rare Earth Elements (REE) gained global recognition for their role in modern technological appliances, especially in the green energy sector.

REEs are a group of fifteen metallic elements of the lanthanide series plus two other chemical elements, yttrium (Y) and scandium (Sc). These last two elements have a similar geochemical behavior to the lanthanides and are therefore considered REEs.

The elements are categorized into two groups: light REEs and heavy REEs. The first are lanthanum to gadolinium; the second terbium to lutetium.

Rare Earth Elements are described as “rare” because of their history. In the 18th and 19th centuries, when they were first discovered, they were identified as “earths” — materials that could not be changed by heat. They were rarer compared to other common “earths,” such as magnesia or lime.

In reality, most of them are pretty common. The only rare earth element to not occur naturally is Promethium (Pm), one of the only two radioactive elements that are followed by a stable element in the periodic table.

Where Are Rare Earth Elements Found?

REEs occur in the form of minerals — like phosphates, silicates, and carbonates — and are commonly found in Earth’s crust. In total, there are 169.1 parts per million (ppm) in Earth’s crust, most of which are heavy REEs.

Rare Earth Element deposits are formed in primary and secondary processes. The first consist of magmatic, hydrothermal, and metamorphic processes, while the second imply weathering and sedimentary transport and are generally formed through the erosion of primary deposits.

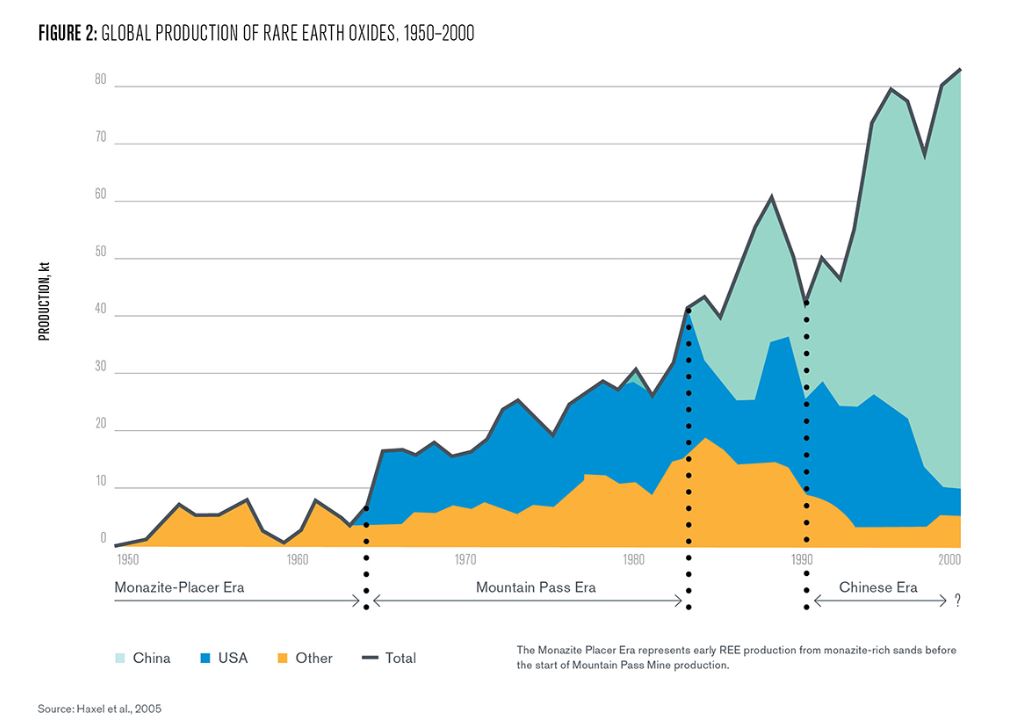

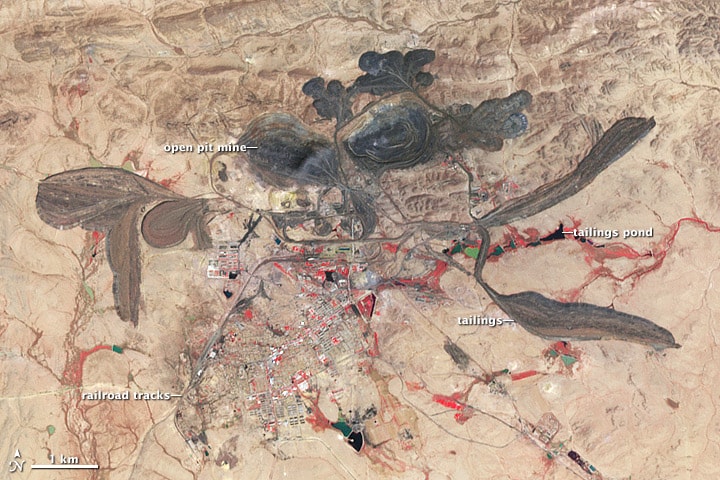

They can be found in many countries, but there are four major deposits of REEs. The Bayan Obo deposit in Inner Mongolia, China, is the biggest rare earth deposit on Earth, first discovered as an iron deposit in 1937. It contains over 57.4 million tonnes of REEs — 97% of which are Light REEs — as well as iron and niobium, and accounts for over 70% of light REEs produced by China.

The second largest REE deposit in the world is located in the USA. The Mountain Pass deposit, situated in the Mojave Desert of California, was first discovered in 1949. It has a huge amount of light Rare Earth compounds compared to heavy ones.

Mount Weld in Western Australia and the Ion adsorption deposits in Southern China are the two other big REE deposits The deposits in Southen China are rich in Heavy REEs, contrary to the other three.

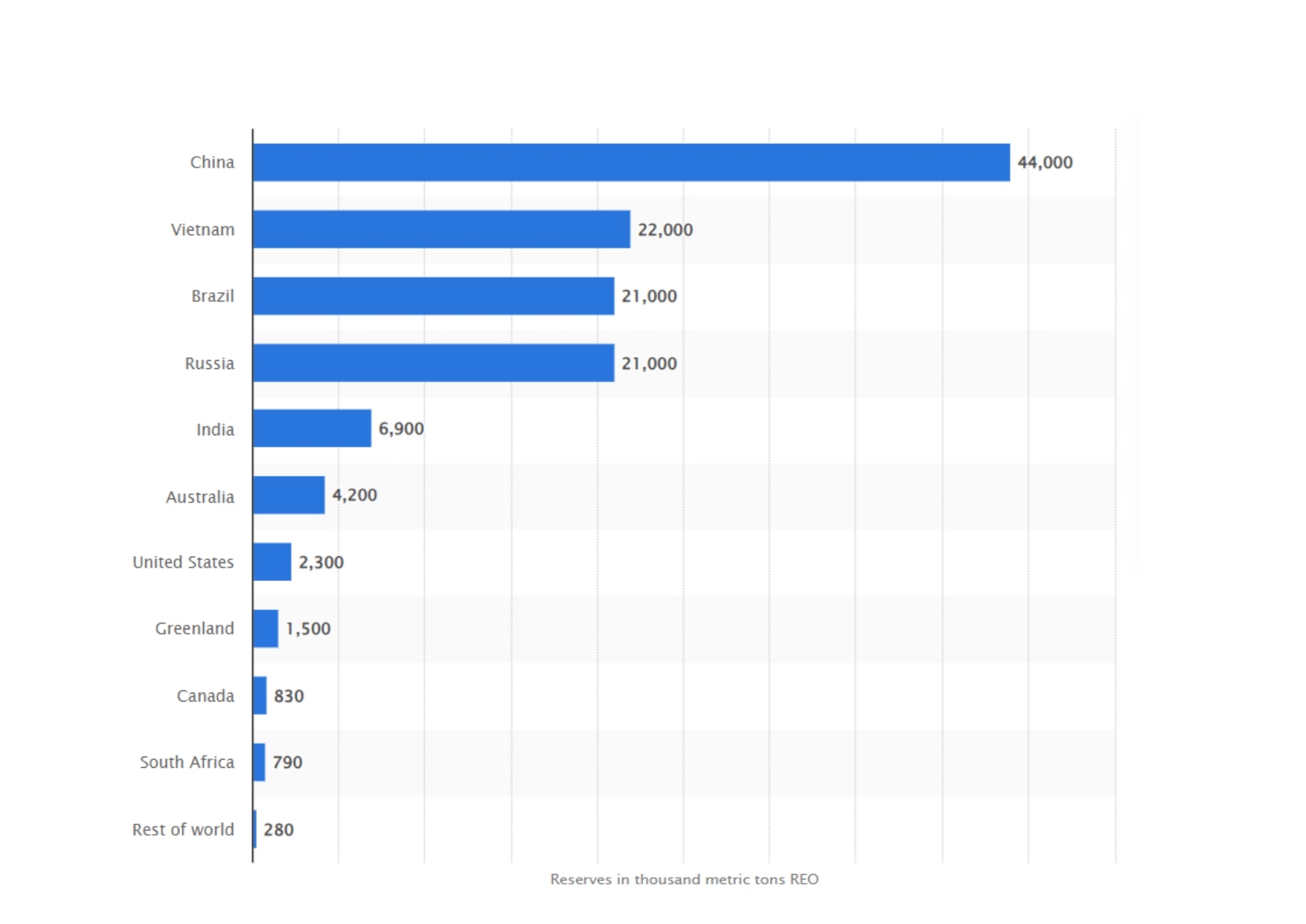

Although there are four major deposits, about 34 countries have REEs in their soils. According to USGS data, China holds about 34% of the world’s REE reserve.s For comparison, Vietnam — the second country for REE reserve — holds about 17% of the global Rare Earth Elements reserve. Russia and Brazil both hold around 16% of REE reserves.

Rare Earth Elements Application: From Industry to Technology

The first reported REE application occurred in Vienna in the 1890s, when lanthanum was used in a commercialized gas mantle. The industrial applications of REEs grew massively since then, earning them the nickname: “Vitamins of Modern Industry.”

Rare Earth Elements are used for their properties — such as thermal stability and high electric conductivity, among others. In fuels, they are used to break down large molecules into smaller hydrocarbons. They are also used in different chemical forms — such as allies, oxides, chlorides, and metals — and as permanent magnets or stabilizers.

At the industrial level, Rare Earth Elements are mainly used in three sectors: green energy, agriculture, and military.

REEs — Heavy REEs, in particular — play a fundamental role in green energy technologies such as solar panels and wind turbines. More recently, REEs’ applications have been expanding to electric vehicles, where they are used for the construction of direct-drive wind turbines and permanent magnet motors.

Related articles: Could Sweden’s Discovery of Rare Earth Minerals Solve Europe’s Supply Problems? | Electric Vehicles Manufacturing: Mining in Western Greenland to Meet Demand | Wind and Solar at COP27: Key Renewable Industries Leading the Energy Transition Together

Rare Earth Magnets are the strongest magnet per unit weight and volume known to humankind. Large wind turbines and electric vehicles usually contain REEs in the form of permanent magnets because of this characteristic.

In agriculture, Rare Earth Elements are used mainly as feeding additives to enhance farm animals’ size. They are also used to increase milk production in dairy cows, egg production in laying hens, and fish’s survival rates.

REEs can also be beneficial to plants. China has been using REEs in fertilizers in soluble forms at low concentrations since 1972, which has resulted in increased quality and yield improvements of various kinds of crops.

Rare Earth Elements play a key role in defense military applications. Permanent magnets — like neodymium iron boron — are used in smart bombs, joint direct attack munitions, joint air, and tomahawk cruise missiles.

However, Rare Earth Elements also touch many aspects of modern life. Specific REEs are used to make screens — from smartphone displays to stadium scoreboards. They can also be used in LED lighting, light bulbs, and televisions, as well as in hard disks and CD-ROM disk drives in computers.

Although they are undoubtedly very useful, there have been some concerns regarding the relationship between REEs and sustainability.

Decarbonization and Sustainability: Rare Earth Elements and the Climate Crisis

After the signing of the Paris Agreement in 2015, society has been focusing on decarbonization. The goal of the agreement is to reduce fossil fuel emissions and switch to a more sustainable economy. Thus, the demand for renewable energy sources has grown considerably in the last decade.

The development of green energy technologies requires the use of permanent magnets, such as Rare Earth Elements, among other things. The production of these natural resources has therefore also been on the rise.

As mentioned before, REEs are used in green energy technologies such as wind turbines, electric vehicles, and solar panels. However, a 2022 study investigating the environmental costs of REEs found that, although green energies emit less fossil fuels, the paper, energy, and water consumption and emissions generated for the manufacture of permanent magnets are still very high.

In the energy production sector, the study found that a 1% increase in green energy production is associated with a 0.90% increase in greenhouse gas emissions and a 0.18% increase in REE resource depletion.

Although Rare Earth Elements are very important in our daily lives and key to green industries, the world cannot afford to not take sustainability into consideration. The extreme weather we are witnessing lately is a sign of the climate crisis. We must be careful with our production choices. Switching from one environmental problem to the other is not the long-term solution.

Editor’s Note: The opinions expressed here by the authors are their own, not those of Impakter.com — In the Featured Photo: Rare-earth oxides. Featured Photo Credit: Peggy Greb.