Initially founded as a research and development laboratory, biotechnology company Episome Biotech is endowing our world with new industrial enzyme technologies that have the potential to reform conventional and unsustainable solutions to problems across a range of industries.

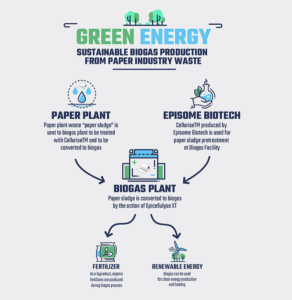

Some of these include the paper and pulp industry, where Episome’s award-winning technology EpiCellulyse XT turns industry waste into biogas and liquid or solid organic fertilizer, thus helping solve both the industry’s problem with pollution (sixth highest polluting in the world) and costly waste disposal in an environmentally and economically efficient manner.

Among the other industries are starch and detergent — where the company’s biological solutions for household product manufacturers promise an eco-friendlier approach that also yields stronger products — as well as biogas, biofuel, textile, leather, rubber and agriculture industries.

To learn more about Episome Biotech and the scope of impact their technologies can have on these industries, in addition to challenges they’re facing and their contributions to realizing the United Nation’s Sustainable Development Goals (SDGs), I spoke to Murat Balaban, company co-founder and CTO.

Could you please share with us how the story of Episome Biotech began?

Murat Balaban: My co-founding partner Murat Bahadir Kilinc and I are friends from high school. We have attended a science focused boarding high school and science was always a major part of our lives. After high school our lives went in different directions, I became a Doctor in Molecular Microbiology in the USA and he became a civil engineer and entrepreneur in Russia. In 2013, we both came back to our home country, Turkey, and decided to run a business that has a solid scientific background. We founded Episome Biotech in 2014 to develop and produce new industrial enzymes that will help the environment.

Your company aims to help quite a few industries become more sustainable and environmentally friendly. If we were to focus on one, could you please explain to our readers how your enzyme technologies can affect the paper industry? What problems can they solve and how?

MB: Paper industry is a booming industry. Everybody thinks that online newspapers and e-books will decrease paper consumption. While the consumption of graphic papers such as newsprint is actually decreasing, the increase in packaging papers (due to a rise in online shopping) and hygienic papers (due to the increased wealth of developing nations) is compensating for this decrease easily.

Paper industry also has a problem, it pollutes the environment. Even the recycled paper industry is a big polluter if the waste is not disposed of safely. For example, to produce one ton of recycled paper, some paper mills produce 250 kg of cellulose based solid waste known as paper sludge. Episome can solve this particular issue. We invented a technology called EpiCellulyse XT to convert this paper sludge into green energy and organic fertilizer.

Since paper sludge cannot be used in biogas production with current technologies, 50 million tons of precious organic waste per year is literally going to waste. With EpiCellulyse XT, the paper sludge can be digested with enzymes and beneficial microorganisms. This process enables us to convert waste cellulose (paper sludge) to biogas, a renewable energy source.

What other methods do we currently have for dealing with this problem?

MB: At present, paper plants either use incineration facilities on-site or off-site, or landfilling.

In your opinion, what are the major challenges your company is facing?

MB: We know our technology is a game changer for paper sludge disposal and that it is very profitable. The payback time is estimated to be three-four years depending on the case. The major challenge we face is the fact that our technology is so novel that it has not been implemented at the industrial level anywhere in the world, yet. Paper industry is a conservative industry and it takes time to convince them to try our method. But we are talking to major industrial partners and big paper plants and are hoping to implement our technology this year at the industrial level.

In addition to your award-winning EpiCellulyse XT, which of your technologies do you think could have the highest impact?

MB: Episome Biotech has expertise in industrial microbiology, we can produce a variety of useful microorganisms and formulate them to be effective in various applications. Recently, we have developed a new product called Green Zebra Biosticks. These are small rods that you can insert into soils of plants that decorate your house or garden. The beneficial microorganisms swim out of these sticks as you water your plant and interact with the roots. There they help the plant to grow, protect it against diseases and improve soil quality.

We believe that biotechnological applications will have a great impact in the agriculture sector, where soils that are contaminated with chemical pesticides and fertilizers need natural boosting. The beneficial microorganisms that we provide are actually naturally found in healthy soils. We just help the soil to go back to its natural, healthy state.

What would you say are the main SDGs (Sustainable Development Goals) that your technologies can contribute to? How?

MB: SDG 7: Our technology helps humanity to reach the clean energy goal. Fifty million tons of paper sludge is produced annually and that amount can generate electricity produced by three nuclear power plants working 24/7. This can be achieved with a single type of waste that can be utilized with our technology. With the advance of science and technology we believe that the earth will be self-sufficient soon, utilizing its own waste as a raw material or as an energy source.

SDG 9: Our technology creates two valuable sources from a waste source. With this innovation, paper plants can be centers for circular economy and clean productivity.

SDG 12: Our technology is based on the idea that one’s waste is another’s treasure. This concept brings us one step closer to a zero-waste industry. Responsible and environment-sensitive production can be reached with this kind of approach. Also, our microbial fertilizer solutions reduce the use of chemical fertilizer and pesticides, making the production of food an environmentally friendly activity.

SDG 13: With the use of renewable energy sources, we reduce the use of fossil fuels and help the earth with its CO2 burden in the atmosphere.

Are you currently working on any other interesting technologies that you would like to share with our readers?

MB: We are working on two main subjects. The first one is increasing Epicellulyse XT’s spectrum. Currently it works with paper sludge but we are working on a new product that will act on underutilized cellulosic waste, like corn and cotton stalks, in an economically feasible manner.

We are also working on previously unknown bacterial beneficial microorganisms that help plants germinate and grow much faster. And of course, this process is done purely by non-GMO microorganisms.