Agrilution is a German startup creating a new home appliance, the plantCube, which will allow anyone to build their own vertical farm at home. The plantCube makes it easy to grow herbs and greens such as basil, baby spinach, arugula, lamb’s lettuce (and many more!). It allows these to grow and flourish in a fresh, fast and pesticide-free manner, contained within a controlled environment that consumes minimal water and energy. The plantCube does so by using an app that can be installed on your phone; it requires no particular skills (nor a green thumb!) as the machine together with the app does it all. Today we are speaking with Max Loessl founder of Agrilution about his idea.

IN THE PHOTO: THE AGRILUTION TEAM. PHOTO CREDIT: @PERALTA.PICTURES

How did you come to the idea behind Agrilution?

Max Loessl: I was travelling around New Zealand in 2012 working for Greenpeace, and I took the time to read a lot and decide what to do with my life in the future. I came across a really interesting book called “The Vertical Farm” which was written by a Professor called Dickson Despommier who taught Medical Ecology at Columbia University in New York; I was so fascinated by this concept of growing food in cities and in controlled environments that I reached out to the author basically asking where I could study something related to this topic in the world. This then started a conversation, and in the end, I decided to move back to Europe. So, I moved to the Netherlands, though I’m originally from Munich, Germany, to study “International Food and Agribusiness” at a university in den Bosch which is in the middle of nowhere in the center of the Netherlands. This university has the biggest research facility for vertical farming. And that is basically how the whole story started; since it was a relatively small and boring town, and I had a lot of time to dive deeper and deeper into the topic, this led to the idea behind Agrilution.

What would be the benefits of using the plantCube?

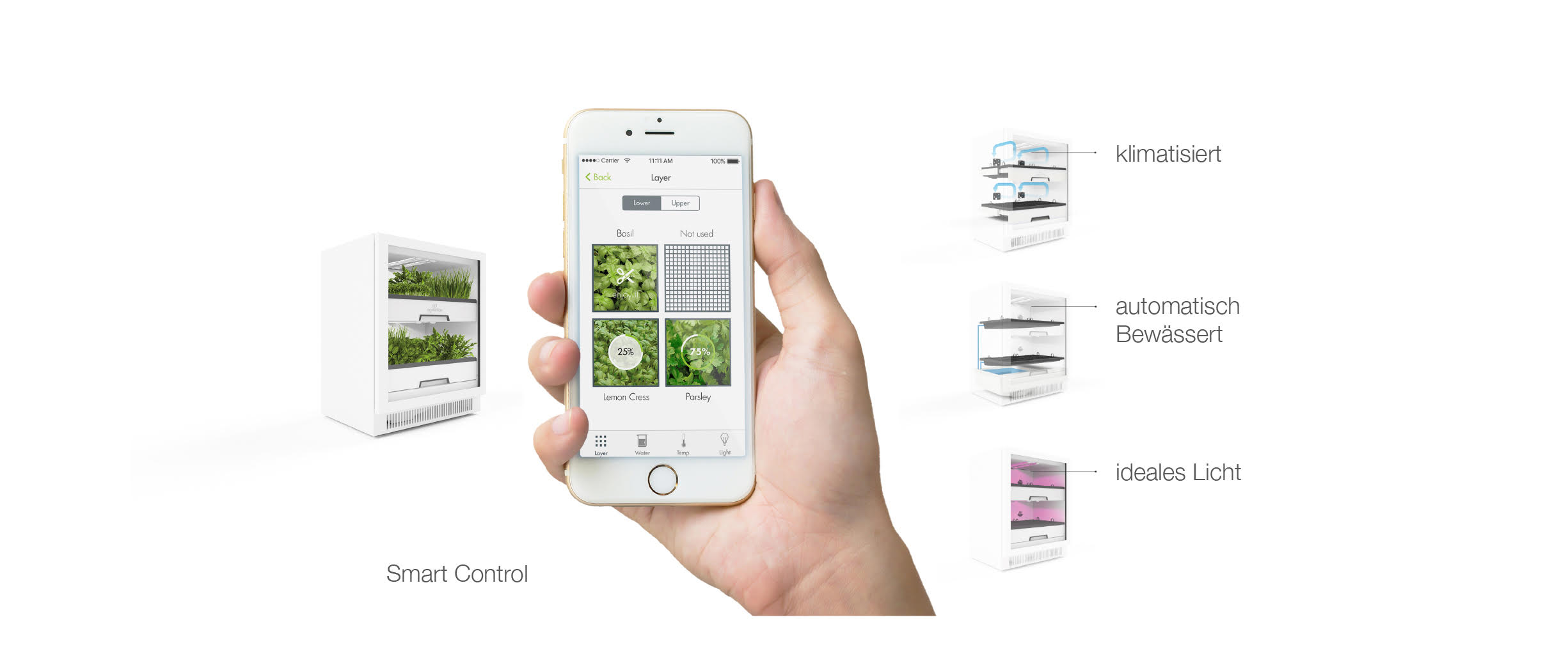

ML: The machine itself is roughly the size of a small dishwasher; you can integrate it into a kitchen. It fits under the counter (at 90 cm in height, 60 cm wide and 60 cm deep), so it follows standard home appliance measurements. It has two layers and it’s equipped with LED lighting for which we have a collaboration with lighting company Osram. It’s hydroponic-based so it waters the plants automatically and it also has full climate control. It’s a closed system. Through this, we can influence plant growth and make sure there is no difference between seasons and regions, because we can influence climate, light, water and the nutrition of the plant. The target is mainly people that live in an urban environment, and it enables them to grow fresh, tasty food all year round. If you were to grow them outside, you probably can only do so in spring and summer; but then in autumn and winter, you can’t grow anything. Also, not everyone has a green thumb. A lot of people tend to kill their plants very easily; the whole point of the machine is so that anyone can have access to fresh food all year round without the need for a green thumb. It takes care of the entire growing process for you, and you don’t need to know anything about plants.

IN THE PHOTO: THE PLANTCUBE . PHOTO CREDIT: @PERALTA.PICTURES

How is it controlled? And what energy and water requirements does the machine have?

ML: It is app controlled. There is a water reservoir in the bottom of the machine which lasts you three to four months; the water itself can be neglected, but there is of course an energy demand because we need to control the climate and of course produce light – but it is also not that much. It is comparable to a computer.

IN THE PHOTO: THE APP SYSTEM. PHOTO CREDIT: @PERALTA.PICTURES

How long ago did you start this project? What kind of customers do you expect to buy your machine?

ML: We been working on this for four and a half years now. We have our first devices already installed in homes here in Germany for our test customers, and we are officially launching it on the market next year. The customers we have now are really diverse; they are not only young people, but also people that are in the age group of our parents. Some people have a garden and they want this just because it is nice to have and so they can grow things they can’t grow in their garden. Other people live in the city and have smaller apartments and want access to fresh food just because, especially here in Germany, most of the supermarkets here close around 8pm. But some people work longer and they need to go to restaurants to get food, so it helps to improve convenience and lifestyle.

Do you have in mind a different bigger version for people who have more space? Do you also envision having more choices in future for greens and vegetables able to be grown?

ML: We are focusing on the end-consumers like private home markets for now, but maybe for the future we can also bring out a bigger version. Plant-wise we are currently growing lot of different herbs and salads – all green vegetables because that is where people have the fastest success factor, so they can start harvesting after one week, in some cases. It ranges between seven and thirty days from when the plants are ready from seed to harvest, and we are also working on strawberries, baby tomatoes and little cucumbers. The problem with these is that those plants take more than three months to reach maturity, so we are trying to figure out ways to shorten that time span so people can have access to the food faster.

IN THE PHOTO: PLANTCUBE IN A KITCHEN. PHOTO CREDIT: @PERALTA.PICTURES

Are you planning to sell your machine to different markets other than Europe? Where do you think you will be able to make a great breakthrough?

ML: Yes, absolutely. Initially we will be focused on Germany because that is where we are and where we are testing the whole concept. Outside Europe, China is probably the most interesting market for this device because people lack transparency on where their food comes from, and they are willing to pay a premium for products so they know it is clean and they know where it come from. It is similar in other markets in Asia, like South Korea or Japan. We have a lot interest from India, so that is definitely something that we will focus on in the near future, but for now, our focus is only on Germany just to test the whole system until it is stable and then begin to grow internationally.

What kind of seeds do you use?

ML: We have a lot of different seed companies we are working with, no one exclusively. We don’t use any genetically modified seeds. We have some organic varieties but also some that are not organic.

Where is the machine produced? What are some of its main technical features?

ML: At the moment we are producing it in Germany. The machine adopts much of a cradle-to-cradle concept, so it can be totally disassembled and taken apart in all of its little parts. There are no parts that are glued; we are trying to avoid unsafe materials or materials that have to be imported from far away. Of course, with electronics this is very difficult, but with everything else that is what we are focusing on. All materials are also food rated, so it’s always safe for people to eat, no matter what part of the machine the food comes into contact with.