Could electric planes be the next big thing for regional and short-haul flights? Ampaire, an innovative aircraft company from Los Angeles, California believes so, and has been working on a project featuring an electric plane with a unique and advanced design.

Here’s what CEO and Co-Founder Kevin Noertker has to say about his company and its vision for the future of electric air travel.

Who are the founders of Ampaire? What is your background?

Kevin Noertker: We have three co-founders: myself, Cory Combs (the CTO) and Ryan Bilton (the CFO). Cory and I met in 2009 while doing research on advanced technology development for Northrop Grumman, and there we had a very solid dynamic as part of a research and development team. After three years, Cory left in order to pursue his passion for clean tech: he always had those two parallel passions for aviation and clean tech/ electric vehicles, so he moved and joined a clean tech startup overseas. I have always been more into the aerospace industry, and I spent seven years at Northrop Grumman.

Since 2010, Cory has been watching the electric vehicles industry and was trying to figure out when the technology was going to enable electric aircrafts which he considered a really exciting opportunity. In late 2015, I was managing a relatively large program at Northrop Grumman, and Cory was still looking at the industry, finally realizing that it was the right time to seriously start developing electric aircrafts. He reached out to me, and I remember our four-hour conversation wherein he convinced me that the future of aviation was electric and the right time to start was right now. At the end of that conversation we decided, along with our third co-founder Ryan, who has more of a background in economics and finance, to start Ampaire. We founded the company on the question: “What is an aircraft able to do, given the current electric vehicle technology?” We founded the company in March 2016, and have been working on it ever since. We are currently located in Los Angeles, and we have grown our team pretty significantly since last year.

IN THE PHOTO: PART OF THE TEAM OF AMPAIRE PHOTO CREDIT: AMPAIREINC

When will your first plane roll out? What kind of plane will it be? Is it going to be hybrid or fully electric?

KN: We are doing benchtop testing first. Some people call it a ‘copper bird’ when you are testing systems and sub systems for ground tests. Next, we will be doing taxi testing and ultimately flight testing on our vehicle – a full-size, six seater aircraft. It will be flying in 2018.

When you look at the applicability of electric technology in air travel, there are a few places where it makes sense to use it initially, and we decided we will be focused on regional air travel. The real sweet spot here is we are going to start with a nine-passenger aircraft. There is, of course, an opportunity in the longer term for a bigger aircraft, but I think it is important that we have a very pragmatic and focused approach on the market. We are an early company and our market approach is critical. The nine-passenger, short-range plane could be considered “the low hanging fruit for the industry”, while I believe in the next few decades we will also see the electrification of larger aircrafts.

The benefits of electric aviation, specifically the operating cost reduction that includes maintenance and fuel cost, only happen when you go fully electric. Hybrid electric is how you could get these longer ranges, other companies are targeting 700- or 800-mile flights with hybrid electric systems. There is some market for those, but we believe that there is a compelling reason to start off fully electric and grow into his type of system. We do have designs for hybrid electric and we have a number of external entities who have asked us to look into hybrid electric systems for them, and we are also pursuing some hybrid electric variants of our electric system.

What kind of battery technology are you using?

KN: When you are looking at the energy density in the battery technology, this is the limiting factor for the range which we can fly. As battery technology gets better, you are able to pack more energy per kilogram of battery and you can extend your range. We are actively researching new technologies, however one of the biggest issues in electric aviation is how you go about certifying and building a safe system. We also believe that in order to improve the efficiency for that certification, we need to use proven technology even if that technology looks like something less exotic. While we keep our eyes on new developments and we are hoping for miracles, we are not baselining or requiring any new technology to be developed in order for us to serve our first customer.

IN THE PHOTO: THE TAILWIND, AMPAIRE’S ELECTRIC PLANE MAQUETTE PHOTO CREDIT: AMPAIREINC

What are the main features of the aircraft?

KN: The aircraft we are working on is called the TailWind. The TailWind has two variants: electric and hybrid electric. When you look at the opportunities for fully electric aircrafts, you have new integration techniques which can improve the efficiency of your flight and decrease the drag. In our design of the TailWind, we get boundary layer ingestion from the ducted fan in the rear. We are also taking advantage of some of that autonomic technology that is available: being able to remove that rear tail and achieve your control through thrust vectoring. This is a technology not available on existing – standard combustion – aircrafts, except on some very exotic cases like military aircraft which are able to use high-cost material to handle the heat of the exhaust. When you are electric you don’t have that hot exhaust, and you can now do thrust vectoring at a reasonable cost for commercial aircrafts.

For new-build airplanes, the integration of an energy storage system is critical, especially when you do it in a more efficient way. What we have seen in building aircraft architectures is that you have more flexibility in the way you balance the weights and balances of your aircrafts, as well as how well and how you integrate your battery system. From a use case design, we are targeting regional air travel, or trips of 350 miles or less. The key there is not necessarily the speed, but as a high-efficiency flight; that is one thing our design is looking into – maintaining efficiency in terms of energy used and the weight of the integration in your plane.

Are you thinking about further developments for your aircraft?

KN: I’ll say we have a number of designs and each of them is tailored to a different use case. We are going to be opportunistic in which part of the industry we tackle, and depending on the use, we have different design points for the aircraft. The aviation industry is at an inflection point. Inflection points are normally driven by new propulsion technology and the electrification of aviation is one of those inflection points. We are really at the beginning of it now, and I see it impacting all regional travel with the possibility of having up to 50-passenger, fully electric aircrafts in the next few decades. We are building our architecture in order to scale that size of aircraft, however technology today is not good enough to do that and we have to wait for improvements in batteries, engines and power distribution systems before we can really get to that 50-passenger plane. I think that is the sweet spot for electric, and you can get some really meaningful cost reduction for the operations.

You can also start to open up the regional air travel market. If you look at all the airports in the USA, for instance, there are about 5,000 airports that are commercially available to fly. However commercial aviation only uses 500 of them – about 10%. The reason airlines don’t fly into these regional airports is not because there is no demand, but because it is not cost effective to fly to most of those airports. It is not profitable to the extent that airlines currently flying to regional airports mostly rely on government subsidies, and are referred to as “essential air services”. The electric aviation industry really is going to open up regional air travel and help us to move away from the congested hubs. You don’t need a 737 for that kind of travel, but only that 50-passenger aircraft which is really going to be perfect in the long run.

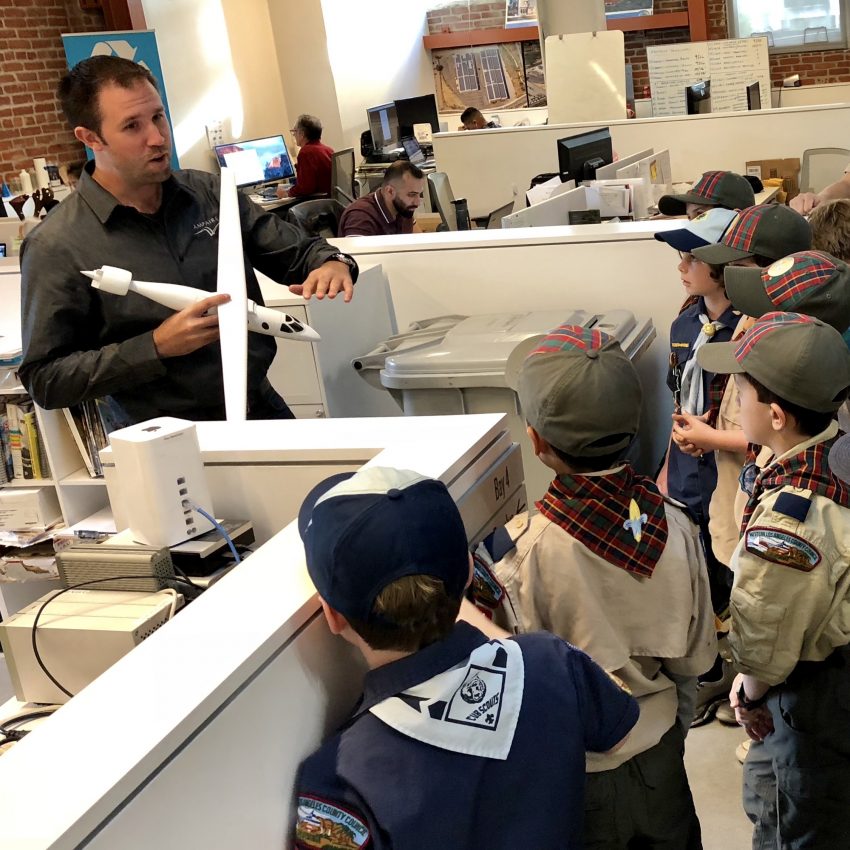

IN THE PHOTO: AMPAIRE’S CEO KEVIN NOERTKER EXPLANING TO BOY SCOUTS THE IDEA OF ELECTRIC AVIATION PHOTO CREDIT: AMPAIREINC

What do you think of concepts such as flying cars and VTOL? Do you see them as competitors?

KN: I’m very excited about the future of vertical takeoff and landing (VTOL) aircrafts. I was in attendance at the Uber Elevate conference when they launched this concept. We founded our company on developing zero emission performance aircrafts, and looked deeply into the VTOL concept, but we are not currently pursuing it as our core business. We have submitted patents on a VTOL aircraft architecture. It is certainly an opportunity, however there are some risks for VTOL airline companies. If the market grows pretty significantly, the biggest hurdles there are going to be in market adoption and the possible growth given noise constraints and range capability of those aircrafts. Ultimately, they are going to start operating within cities which is the good use case of some Uber presentations. If you start to dig into how much noise each aircraft makes, they are quieter than your traditional helicopter, but you still have to consider how many cycles of takeoffs and landings will be required, and the space that will be needed in an urban setting. This is ultimately what I believe is going to be the limit: the aggregate noise generated by that fleet of aircrafts. I’m worried that the market might not grow as quickly as some are projecting due to these constraints. With that said, I really hope they will be able to overcome the constraints: I don’t see them as a direct competitor to what we are doing at Ampaire and I’m absolutely excited about the idea of having the opportunity in the future to fly on one of those myself.

RELATED ARTICLES

“PIPISTREL: A GAME CHANGER IN THE SUSTAINABLE AVIATION INDUSTRY by Alessandro du Bessé

“ZUNUM AERO: MAKING ELECTRIC PLANES POSSIBLE” by Alessandro du Bessé